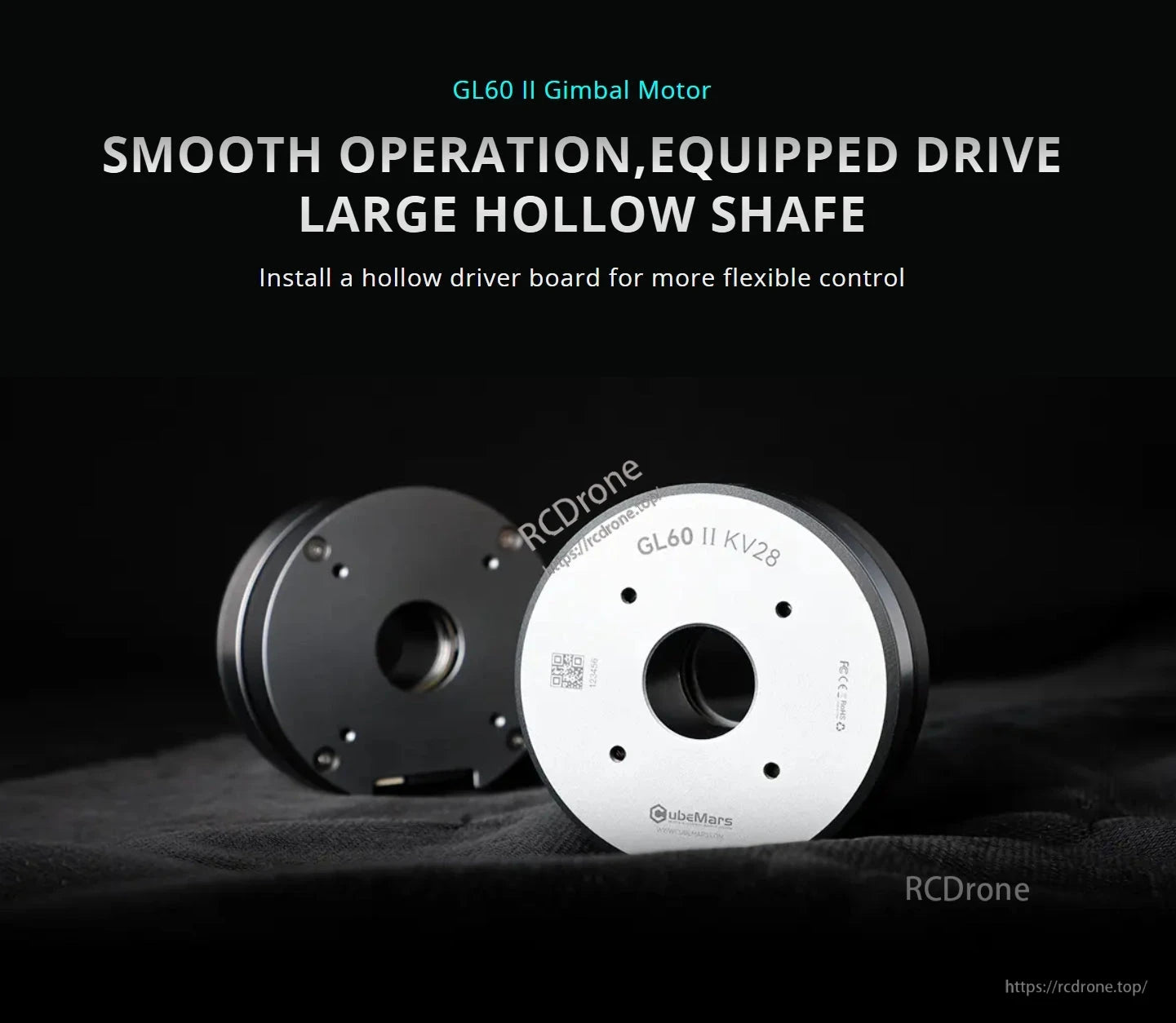

The CubeMars GL60 II KV28 Gimbal Motor is engineered for high-end gimbal systems and autonomous driving applications, delivering exceptional low-speed stability, precision control, and high reliability. Featuring a new-generation hollow drive board, the GL60 II reduces cogging torque by 37.5% (from 2.4 cN·m to 1.5 cN·m) through an upgraded electromagnetic design and optimized motor structure, significantly improving low-speed servo performance.

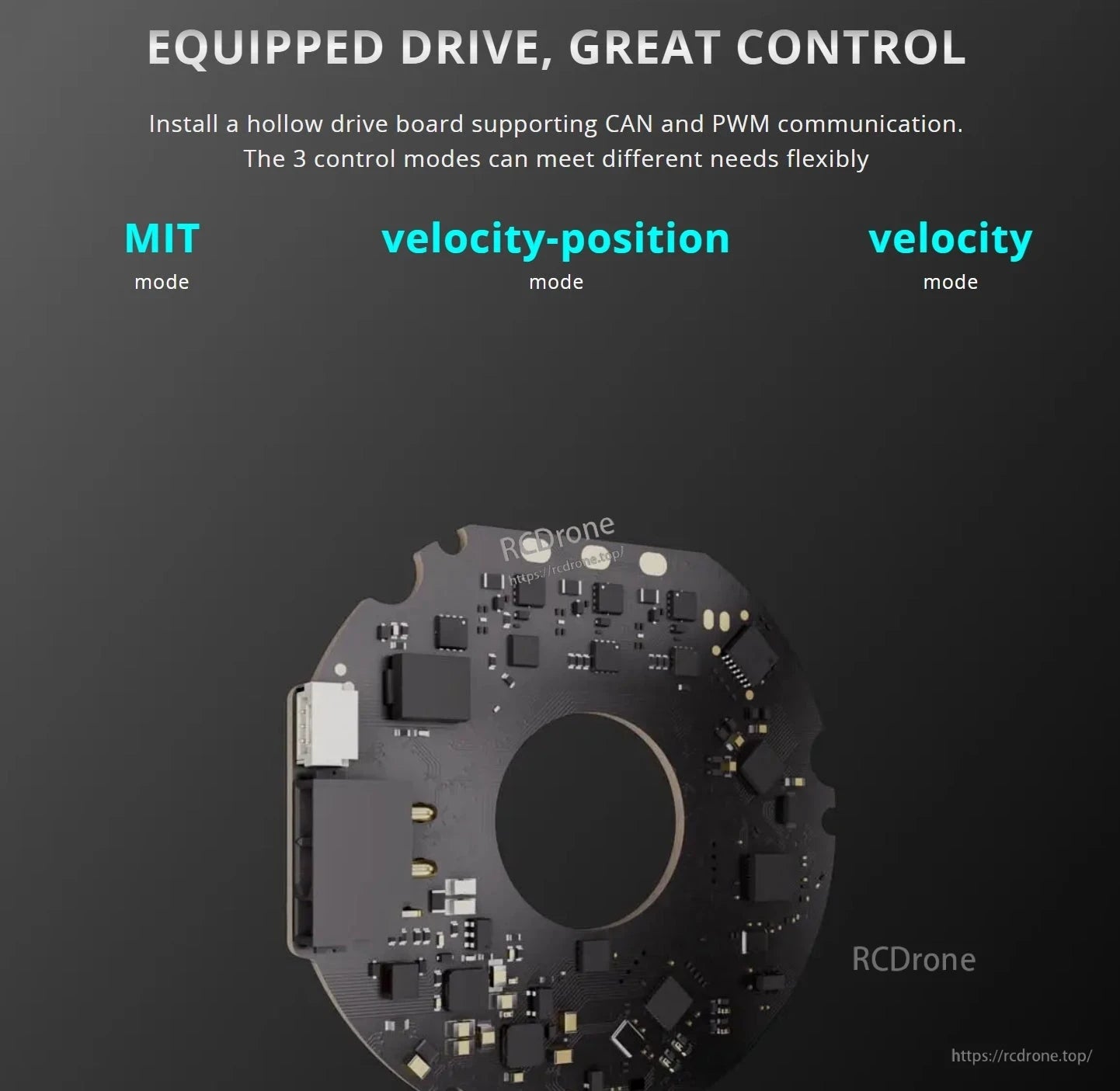

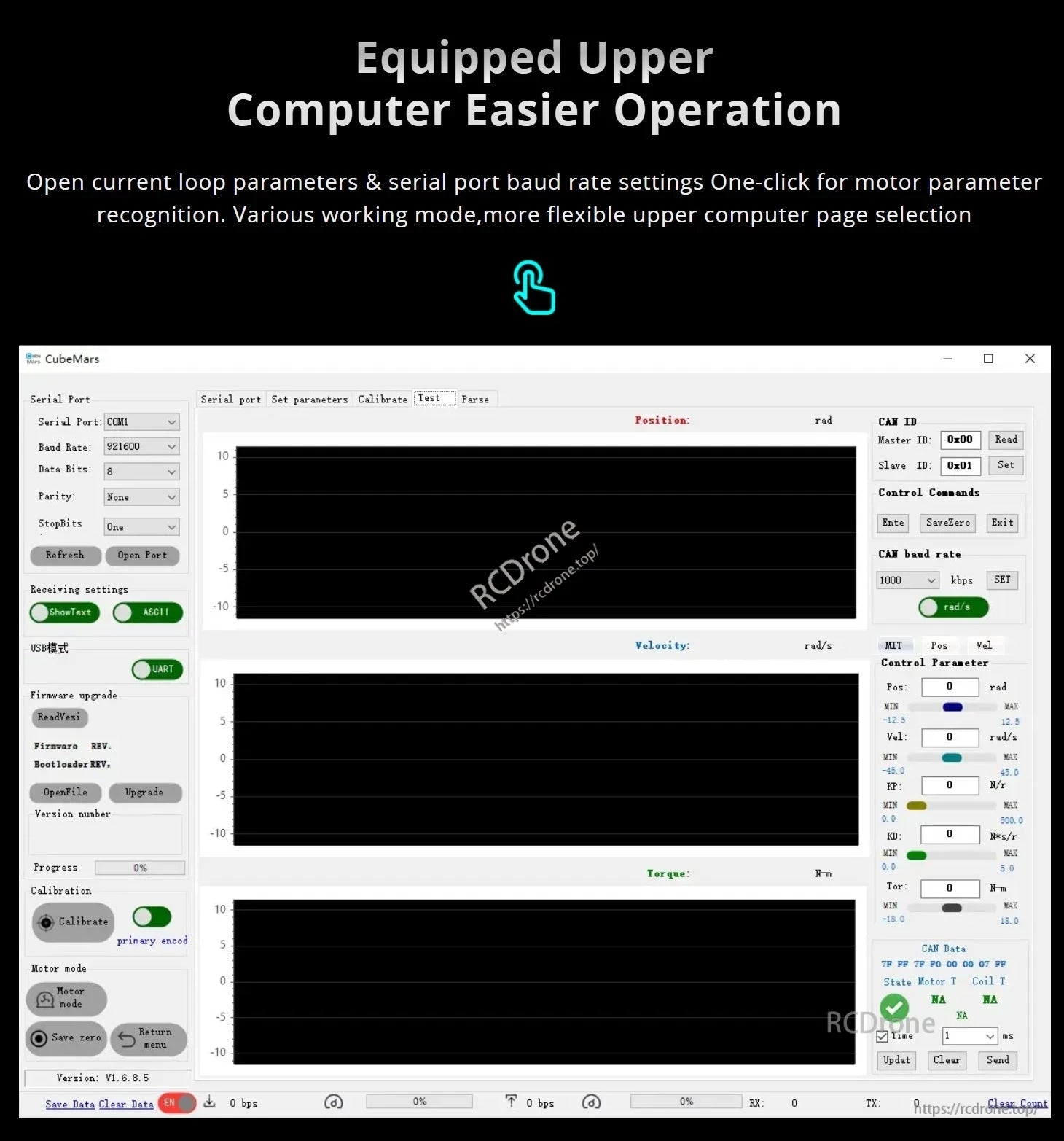

Equipped with both CAN and PWM communication, the motor supports three control modes: MIT mode, Velocity-Position mode, and Velocity mode, enabling flexible configuration for different application needs. The dual-port design includes a black XT30 2+2 interface (integrating power and CAN signal cables for secure, reliable transmission) and a white CJT-3Pin interface (for upper-computer connection, real-time parameter adjustment, and efficient debugging).

With one-click motor parameter recognition via the host computer software, users can easily set current loop parameters, adjust serial port baud rates, and select working modes from an intuitive interface. The large φ20 mm hollow shaft allows more slip ring accommodation, supporting complex wiring requirements in professional gimbal systems.

This motor is designed for industrial-grade stability, making it ideal for gimbal stabilization systems, autonomous vehicle sensors, and other precision-control applications.

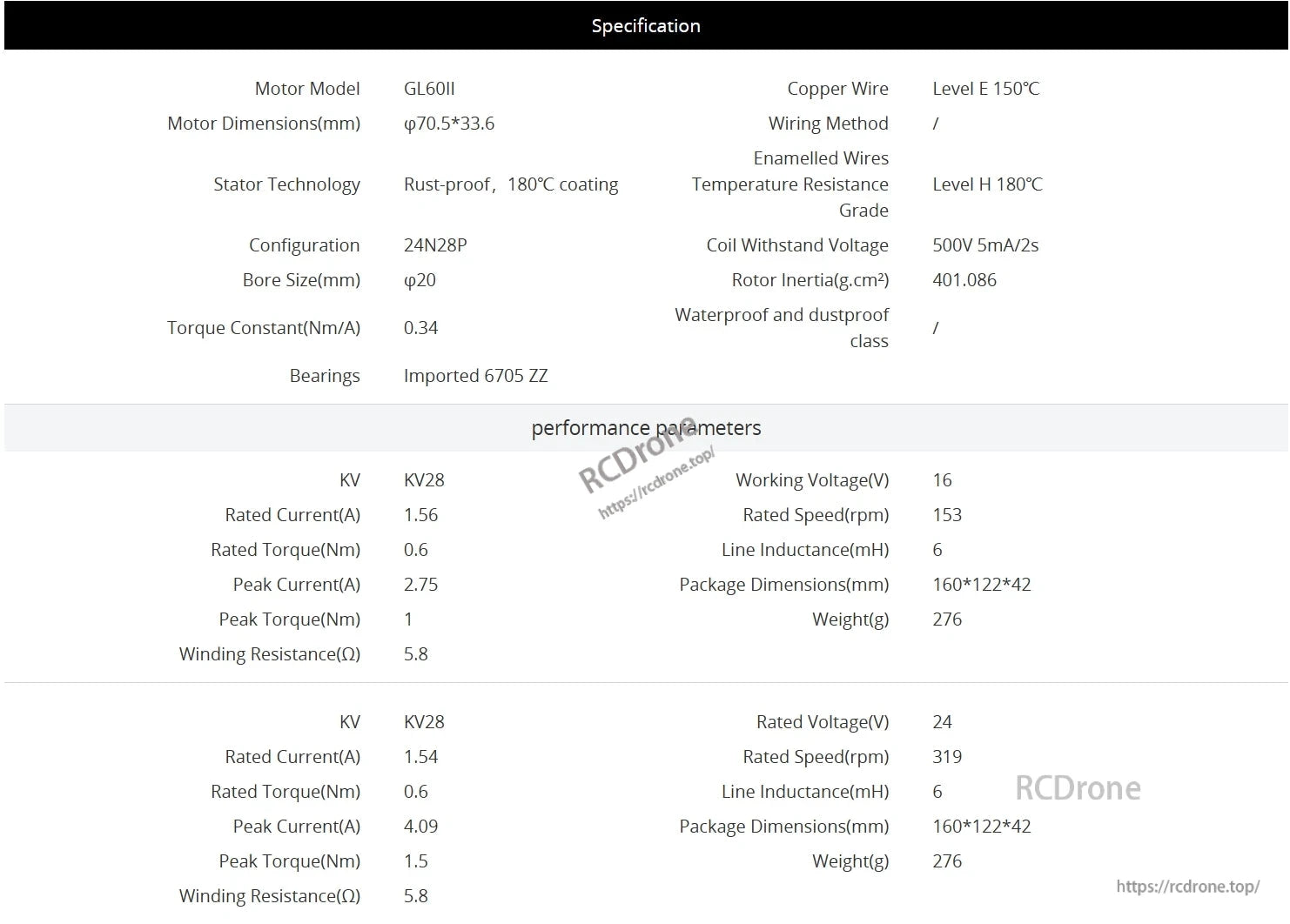

Specifications

| Parameter | Value |

|---|---|

| Motor Model | GL60II |

| Motor Dimensions (mm) | φ70.5 × 33.6 |

| Stator Technology | Rust-proof, 180 °C coating |

| Configuration | 24N28P |

| Bore Size (mm) | φ20 |

| Torque Constant (Nm/A) | 0.34 |

| Bearings | Imported 6705 ZZ |

| Copper Wire | Level E 150 °C |

| Enamelled Wire Temp Resistance Grade | Level H 180 °C |

| Coil Withstand Voltage | 500 V, 5 mA/2s |

| Rotor Inertia (g·cm²) | 401.086 |

| Waterproof/Dustproof | / |

Performance Parameters (KV28)

| Rated Voltage (V) | Working Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Torque (Nm) | Peak Current (A) | Peak Torque (Nm) | Winding Resistance (Ω) | Line Inductance (mH) | Weight (g) |

|---|---|---|---|---|---|---|---|---|---|

| 16 | 16 | 1.56 | 153 | 0.6 | 2.75 | 1.0 | 5.8 | 6 | 276 |

| 24 | 24 | 1.54 | 319 | 0.6 | 4.09 | 1.5 | 5.8 | 6 | 276 |

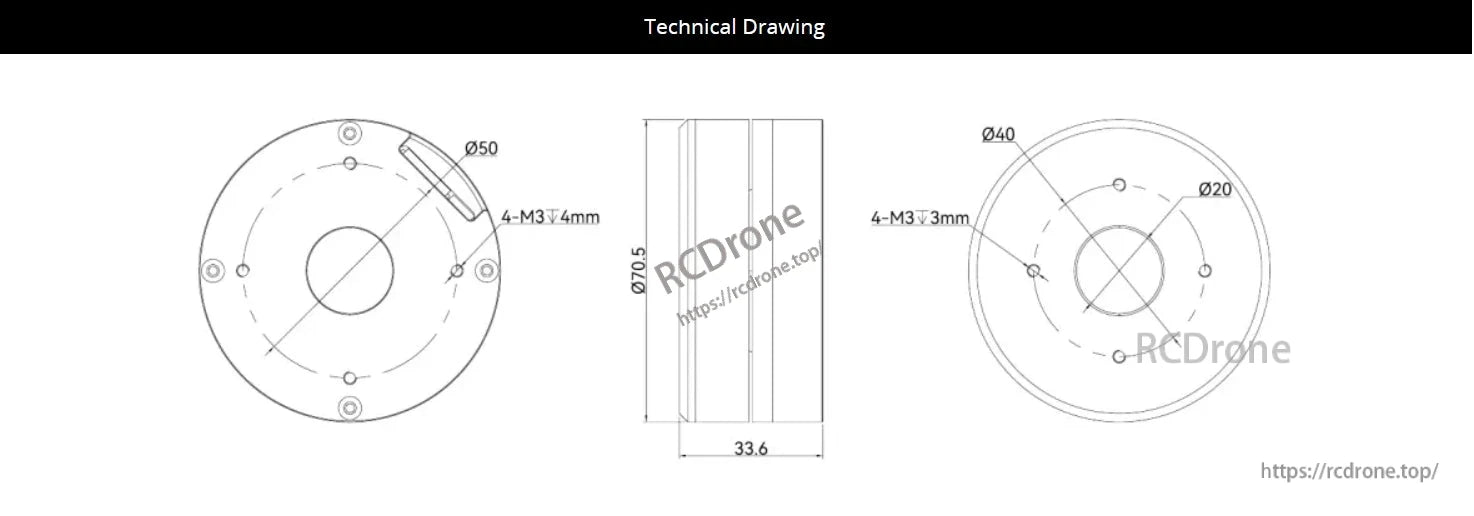

Technical Drawing

-

Outer Diameter: φ70.5 mm

-

Bore Diameter: φ20 mm

-

Mounting: 4 × M3 screws

-

Depth: 33.6 mm

-

Bolt Circle Diameters: φ50 mm (front), φ40 mm (rear)

Manual Downloads

Key Features

-

New Hollow Drive Board – Allows compact integration with large hollow shaft.

-

37.5% Cogging Torque Reduction – From 2.4 cN·m to 1.5 cN·m for superior low-speed stability.

-

CAN & PWM Communication – Flexible control system integration.

-

Three Control Modes – MIT, Velocity-Position, Velocity.

-

Dual Interface Design – XT30 2+2 for power & signal; CJT-3Pin for debugging.

-

One-Click Motor Parameter Recognition – Fast setup and tuning.

Applications

-

Professional gimbal stabilization for aerial, land, or marine platforms.

-

Autonomous driving systems requiring precision sensor alignment.

-

High-precision optical equipment.

-

Robotics where smooth, low-speed control is critical.

Details

CubeMars GL60 II KV28 Gimbal Motor dimensions: Ø70.5 x 33.6 mm, Ø40 and Ø20 holes, 4-M3 screws with 4mm and 3mm depths.

CubeMars GL60 II KV28 Gimbal Motor: φ70.5*33.6 mm, 180°C coating, 24N28P config, 0.34 Nm/A torque, 1.56 A rated current, 0.6 Nm torque, 153 rpm speed, 16V working voltage, 276g weight, waterproof/dustproof design.

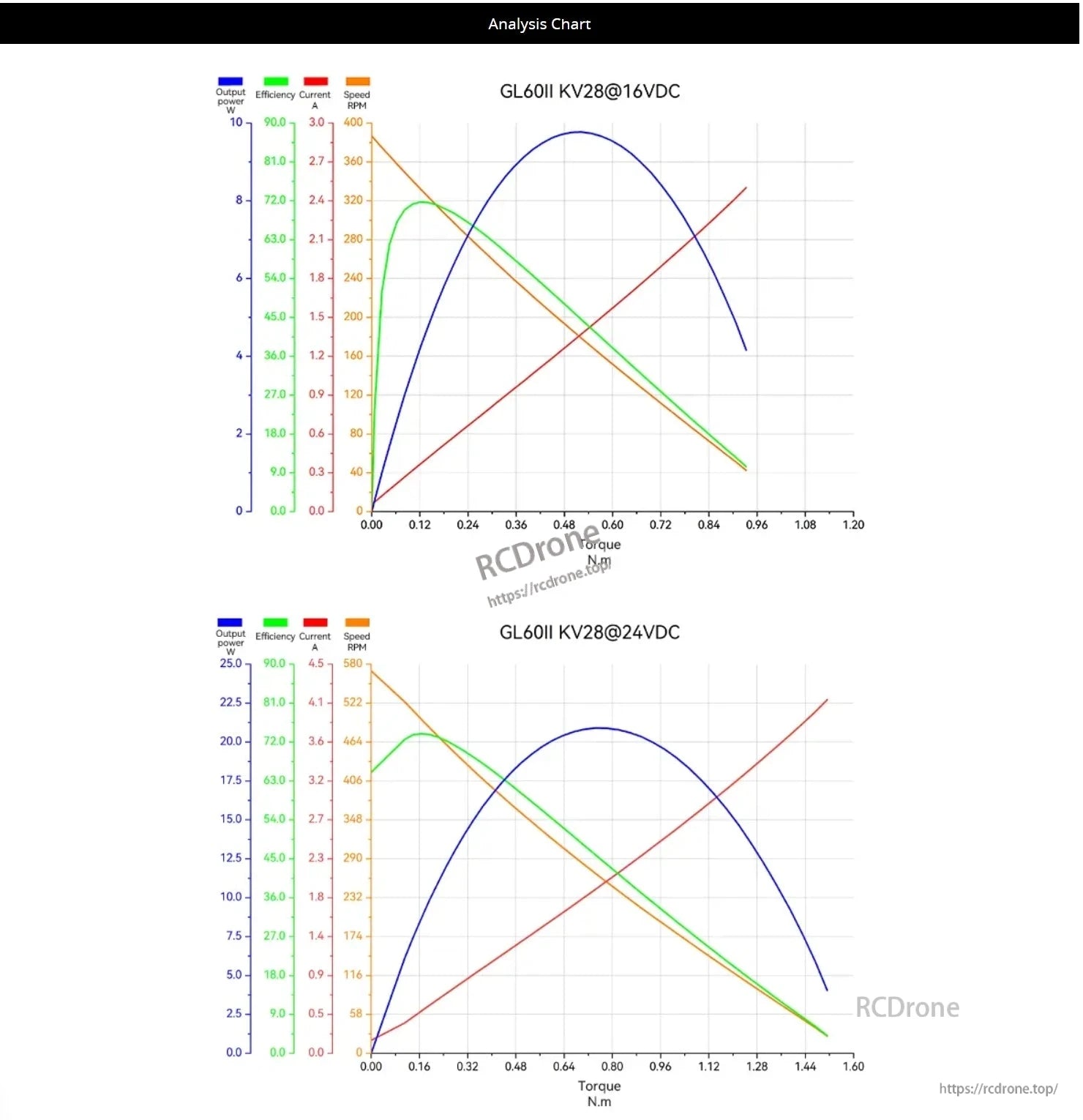

CubeMars GL60 II KV28 Gimbal Motor analysis charts display output power, efficiency, current, and speed at 16VDC and 24VDC, with torque as the variable. Data highlights motor performance metrics.

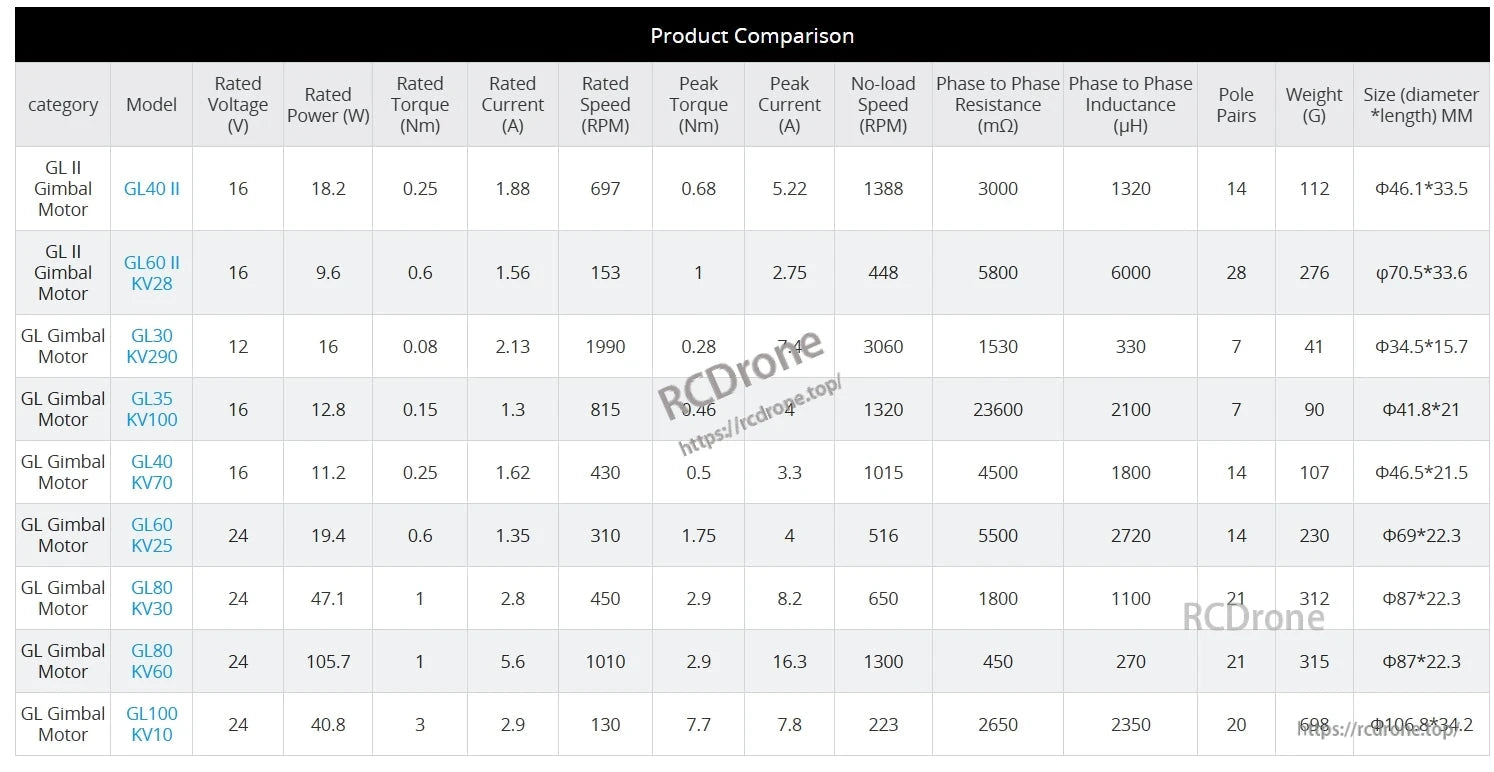

GL60 II KV28 Gimbal Motor: 16V, 9.6W, 0.6Nm torque, 1.56A current, 153 RPM speed, 1Nm peak torque, 2.75A peak current, 448 no-load RPM, 28 pole pairs, 276g weight, 70.5x33.6mm size.

CubeMars GL60 II KV28 Gimbal Motor offers smooth operation, equipped drive, large hollow shaft for flexible control.

CubeMars GL60 II KV28 Gimbal Motor: Equipped drive, great control. Supports CAN, PWM; offers MIT, velocity-position, velocity modes.

Upgraded EM, lower cogging torque. Enhanced electromagnetic design reduces torque from 2.4 cN.m to 1.5 cN.m for better low-speed servo performance.

Black & White Dual Interface Free for debugging. XT30 2+2 combines power and CAN signal cables for reliable transmission. CJT-3pin connects to upper computer for communication and parameter adjustment.

CubeMars GL60 II KV28 Gimbal Motor interface. Equipped upper computer for easier operation. Features include loop parameters, serial port settings, motor recognition, and flexible page selection. Displays position, velocity, and torque graphs.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...