Overview

The HOBBYWING H8M 8108 85KV brushless power system is an industrial-grade solution designed for single-axis loads ranging from 2.5 to 3.5 kg, with a maximum pulling force of 7.4 kg. It is compatible with 30mm carbon fiber tube arms and boasts an IP45 waterproof protection rating. Offering efficient heat dissipation, it serves as a versatile power solution for various applications, including small professional aerial photography, police operations, security, surveying and mapping, emergencies, and more.

The FOC ESC (Electronic Speed Controller) features CAN communication, a dual redundant design for digital and PWM throttle options, power-on self-test, fault storage, over-current protection, stall protection, and other protective functions.

Hobbywing H8M Motor Specifications

|

Specifications |

Max Thrust: Recommended Battery: |

7.5kg 12S |

|

|

Motor |

Stator Size: |

Φ81*8 mm |

|

|

ESC |

ESC: |

60A-FOC

CAN |

|

|

Propeller |

Diameter X Thread Pitch:

|

30*9.8"

|

Details

Diagram includes dimensions: 140.00, 30.00, 87.00, 28.70, 34.70, 20.00, 9.00, 33.00, 19.00, 4.00, and 10.00 for mechanical part specifications.

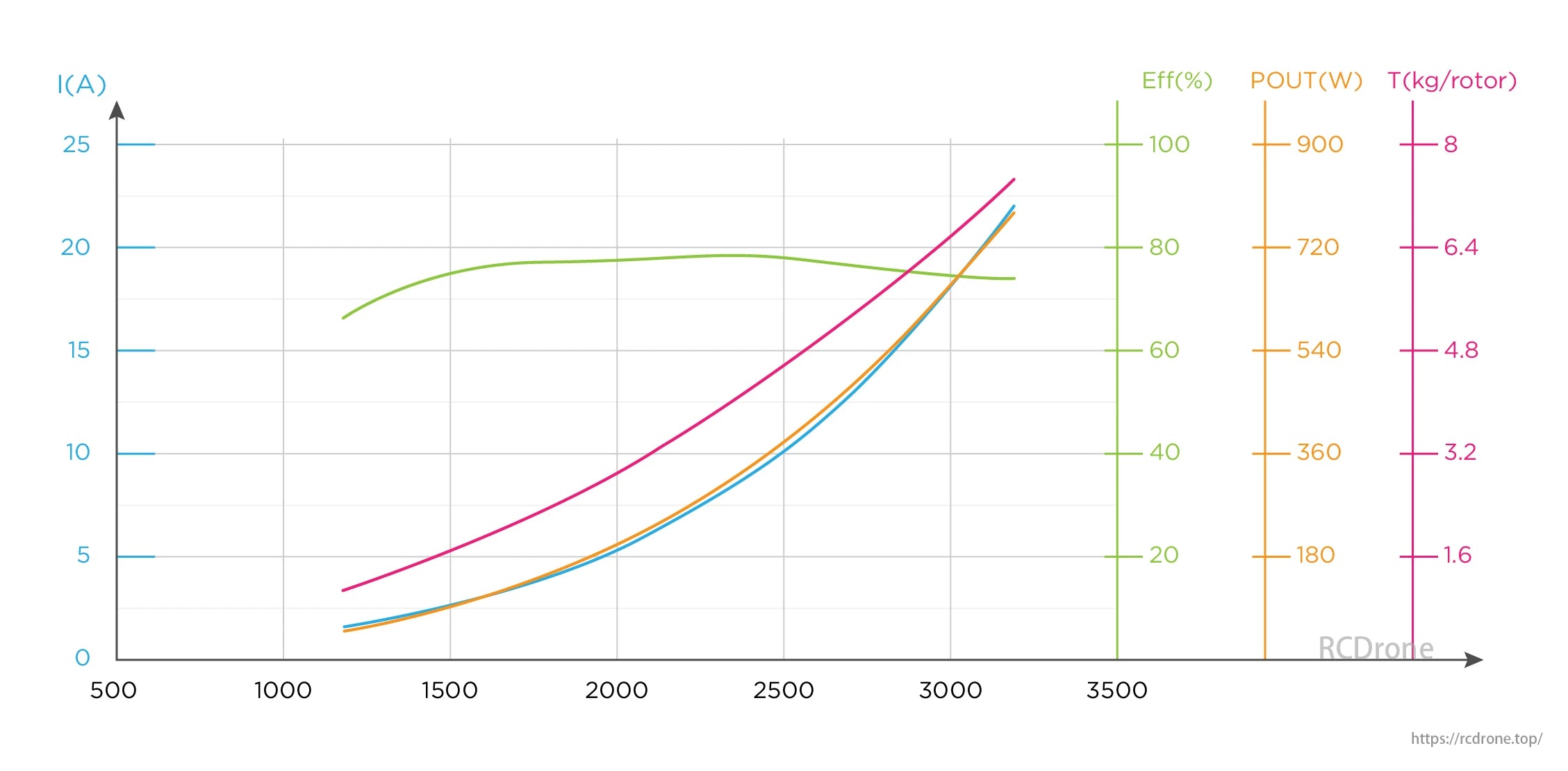

Graph displays current (I), efficiency (Eff%), power output (POUT), and torque (T) across a range of values, with I peaking at 25A and Eff% reaching 100%.

|

Voltage(V) |

Propeller(Inch) |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

RPM |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

48V (12S LIPO) |

30*9.8" |

30% |

975 |

1.2 |

57.1 |

1165 |

17.1 |

55.0 |

|

33% |

1180 |

1.5 |

70.6 |

1275 |

16.7 |

|||

|

36% |

1470 |

2.0 |

94.1 |

1420 |

15.7 |

|||

|

39% |

1715 |

2.4 |

116.2 |

1534 |

14.7 |

|||

|

42% |

1945 |

2.9 |

139.3 |

1634 |

14.0 |

|||

|

45% |

2315 |

3.7 |

179.1 |

1783 |

12.9 |

|||

|

48% |

2595 |

4.4 |

211.3 |

1887 |

12.3 |

|||

|

51% |

2995 |

5.4 |

260.3 |

2026 |

11.5 |

|||

|

54% |

3265 |

6.1 |

294.8 |

2114 |

11.1 |

|||

|

57% |

3510 |

6.8 |

327.5 |

2190 |

10.7 |

|||

|

60% |

3865 |

7.9 |

377.0 |

2295 |

10.2 |

|||

|

63% |

4275 |

9.1 |

437.9 |

2410 |

9.8 |

|||

|

66% |

4505 |

9.9 |

473.5 |

2472 |

9.5 |

|||

|

69% |

4865 |

11.1 |

533.0 |

2565 |

9.1 |

|||

|

72% |

5270 |

12.6 |

603.6 |

2666 |

8.7 |

|||

|

75% |

5470 |

13.3 |

640.6 |

2715 |

8.5 |

|||

|

78% |

5895 |

15.1 |

722.7 |

2814 |

8.2 |

|||

|

81% |

6195 |

16.3 |

783.7 |

2882 |

7.9 |

|||

|

84% |

6405 |

17.2 |

826.9 |

2929 |

7.7 |

|||

|

87% |

6685 |

18.5 |

886.0 |

2990 |

7.5 |

|||

|

90% |

7025 |

20.0 |

958.5 |

3063 |

7.3 |

|||

|

100% |

7520 |

22.1 |

1060.3 |

3166 |

7.1 |

H Series: Reliable, efficient power solution for multi-rotor platforms. Designed for high-end industrial drones, solving one-stop power problems effectively. Buy now.

Integrated power system, convenient, efficient and stable for drone operation.

Power system for industrial uses like aerial photography, surveying, inspections, monitoring, and public safety. H6M: 2.5kg/rotor, 9.3g/w efficiency. H8M: 3kg/rotor, 11.5g/w efficiency.

Integrated ESC and Motor Units offer convenience, efficiency, stability. Easier installation, smooth drive, efficient flight with self-developed sine wave (FOC) ESC.

Dual throttle control enhances flight assurance. CAN design improves performance and interference resistance, ensuring safety. PWM and CAN switch seamlessly in ≤16 milliseconds.

Real-time data storage monitors function, correcting issues. CAN bus records power system status, storing and transmitting failure data. Fault codes diagnose problems via DATA LINK.

All-new design features built-in centrifugal fan for efficient heat dissipation, 15-20°C cooler temperature, and CD pattern rotor. Waterproof and dustproof with IPX5 rating, ensuring reliability in various conditions.

Premium materials and advanced technology. H+ high-temperature enameled wire exceeds 200°C. Passed -20-60°C extreme environment test. Imported waterproof ball bearings. High-performance, arc-shaped thick magnets enhance performance by over 10%.

Technical parameters for H6M and H8M motors are detailed, including voltage, propeller size, throttle percentage, thrust, current, power, RPM, efficiency, and temperature. Data is measured at sea level altitude in a 25°C room. Throttle adjusts tension; motor temperature reflects rated throttle operation over 10 minutes.

Size specifications include dimensions like 114.85, 31.55, and 28.55 mm, with various holes and screw details such as M3-6H and 8 x M3.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...