Overview

The T-Motor F60 Pro IV 2207.5 Brushless Motor is engineered for extreme FPV racing and freestyle performance. Available in 1750KV, 1950KV, and 2550KV variants, this motor delivers precise throttle control, explosive thrust, and increased crash resistance—making it a popular upgrade for drones like Nazgul5 X220S.

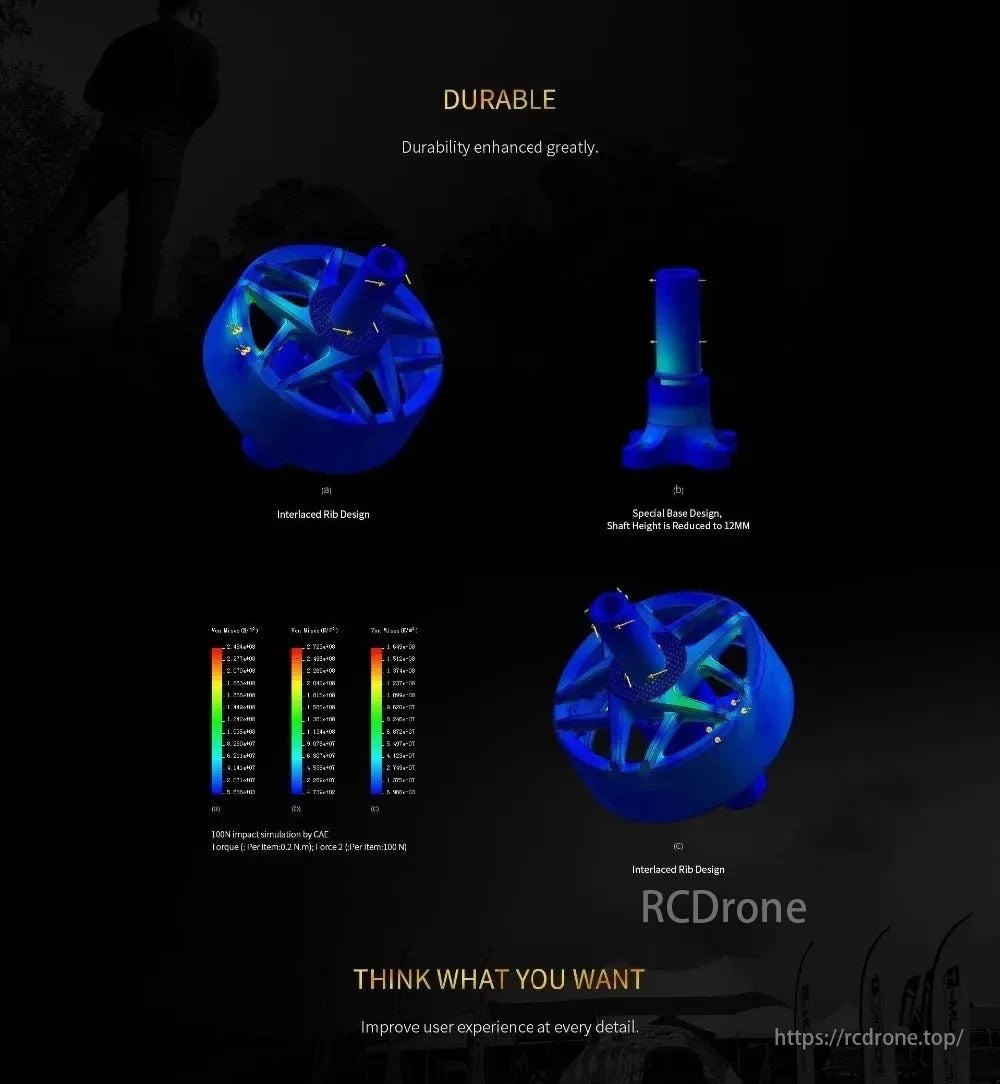

Compared to the F60 Pro III, the Pro IV version features a 9% weight reduction, quicker throttle response, and a more durable rib-reinforced design, offering both smoother flight and higher efficiency.

Key Features

-

KV Options: 1750KV (high efficiency), 1950KV (balanced), 2550KV (maximum speed)

-

Voltage Range: 4S–6S Lipo compatible

-

Max Thrust: Up to 1951g (1950KV + GF5149, tested)

-

Improved cooling with interlaced ribbed design

-

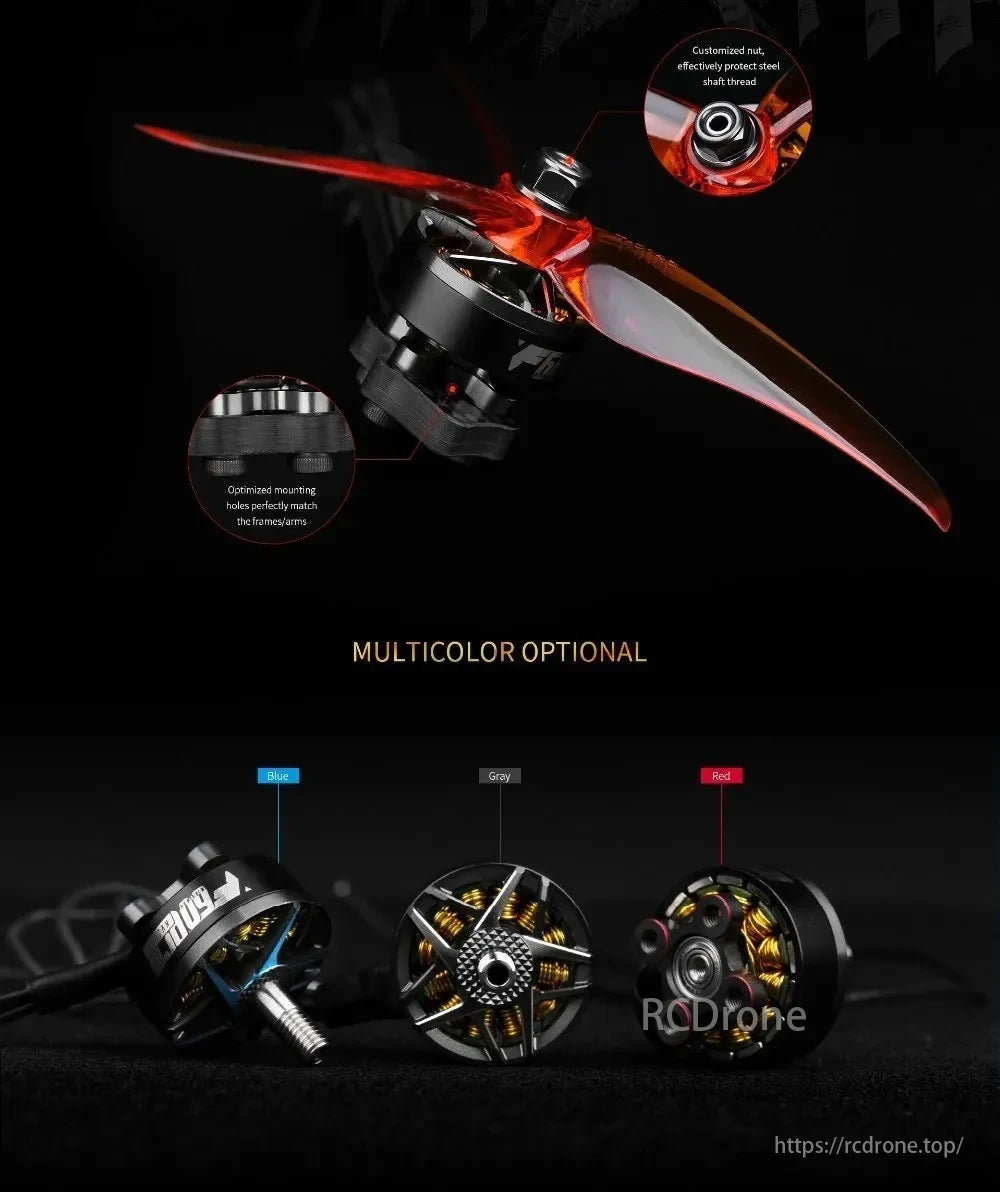

Customized prop nut protects the shaft and ensures secure fit

-

12N14P configuration and 4mm shaft for maximum torque and durability

-

Ultra-light design: ~32g including wire, helps reduce overall drone weight

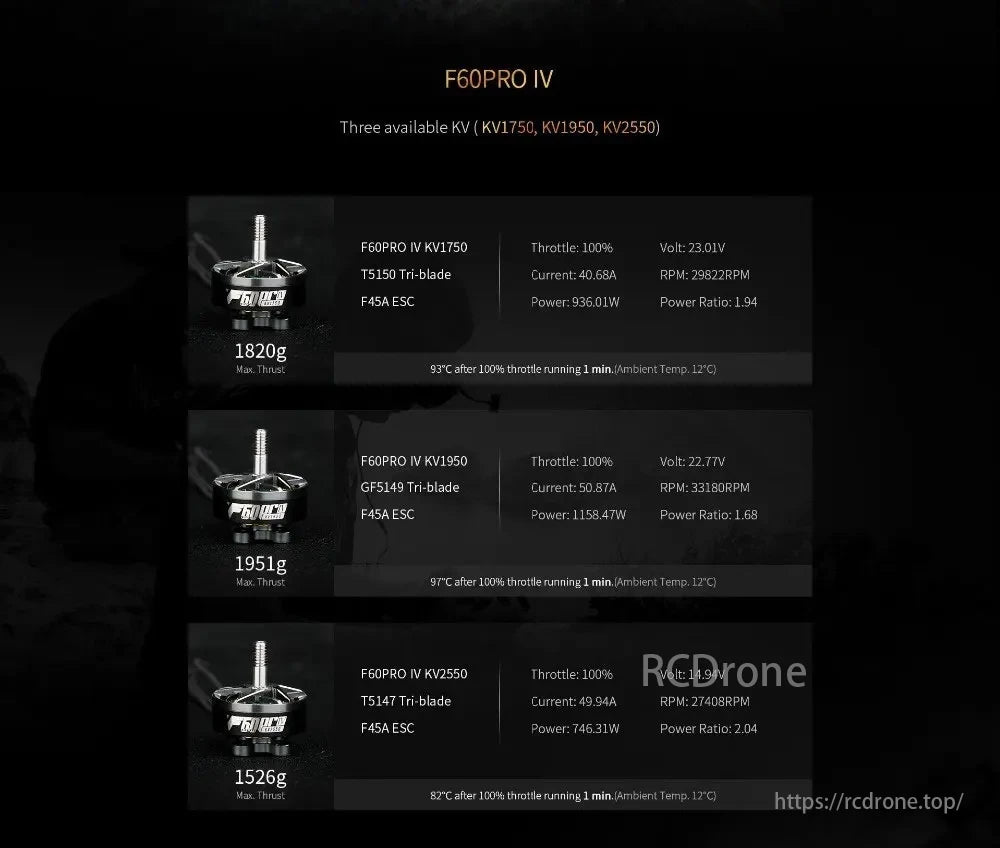

Performance Data (100% Throttle)

| KV | Max Thrust | Power Draw | RPM | Temperature |

|---|---|---|---|---|

| 1750KV | 1820g | 936W | 29822 RPM | 93°C |

| 1950KV | 1951g | 1158W | 33180 RPM | 97°C |

| 2550KV | 1526g | 746W | 27408 RPM | 82°C |

Tested with T5150/GF5149/T5147 props on F45A ESCs at ambient 12°C.

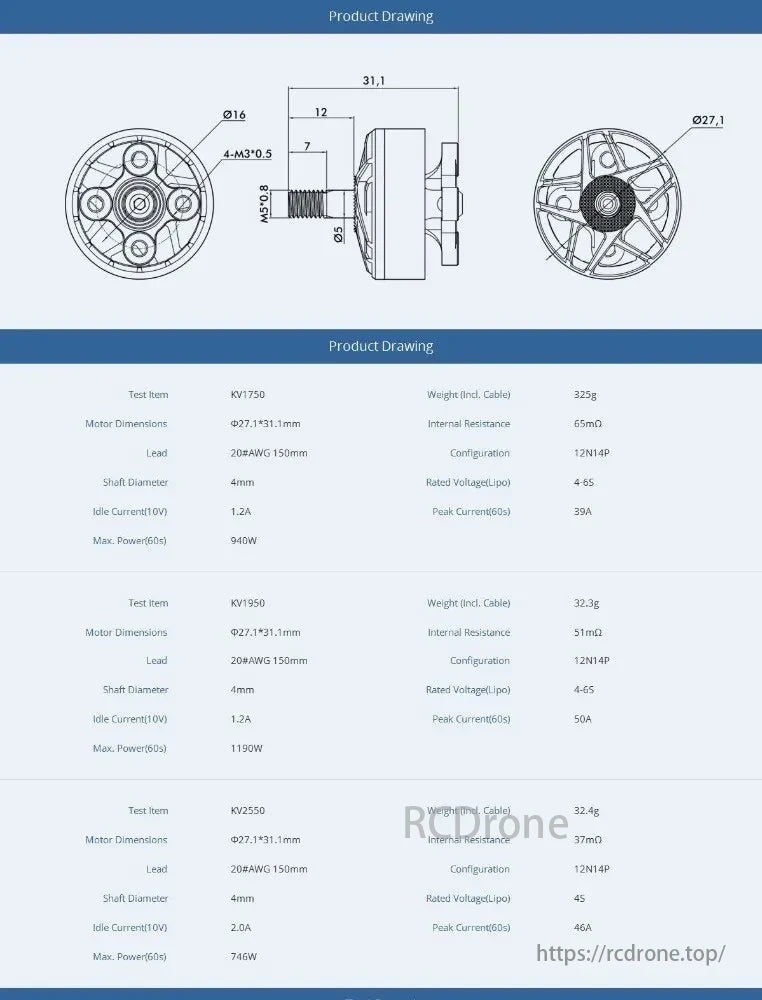

Specifications

| Model | 1750KV | 1950KV | 2550KV |

|---|---|---|---|

| Max Power | 940W | 1190W | 746W |

| Peak Current | 39A | 50A | 46A |

| Idle Current | 1.2A | 1.2A | 2.0A |

| Internal Resistance | 65mΩ | 51mΩ | 37mΩ |

| Weight (incl. cable) | 32.5g | 32.3g | 32.4g |

| Shaft Diameter | 4mm | 4mm | 4mm |

| Motor Dimensions | Φ27.1×31.1mm | Φ27.1×31.1mm | Φ27.1×31.1mm |

| Lead Wire | 20#AWG 150mm | 20#AWG 150mm | 20#AWG 150mm |

Package Includes

-

1 x T-Motor F60 Pro IV 2207.5 Brushless Motor (KV optional)

-

1 x Propeller Nut

-

4 x Mounting Screws

T-Motor F60 Pro: Lighter, more agile. Easy cornering, durable, accurate control. Features sleek design with vibrant accents.

F60PRO IV motor specs: KV1750, 1950, 2550. Max thrusts: 1820g, 1951g, 1526g. Details: voltage, current, power, RPM, temperature after 1 min at full throttle.

Lighter and quicker response. Crafted design reduces weight by 9% compared to F60PRO III. Includes silicon steel sheet, internal motor pinhole, 12MM steel shaft, and customized silicone wire for enhanced performance.

T-Motor with enhanced rib and base design, 12MM shaft, reliable 100N impact simulation, improves user experience in every detail.

T-Motor with customizable nut, optimized mounting holes, and multicolor options: blue, gray, red.

T-Motor details: KV1750, KV1950, KV2550. Dimensions 27.1x31.1mm, 4mm shaft. Weights 32.4-325g, resistances 37-65mΩ. Configurations 12N14P, voltages 4-6S, currents 39-50A, powers 746-1190W.

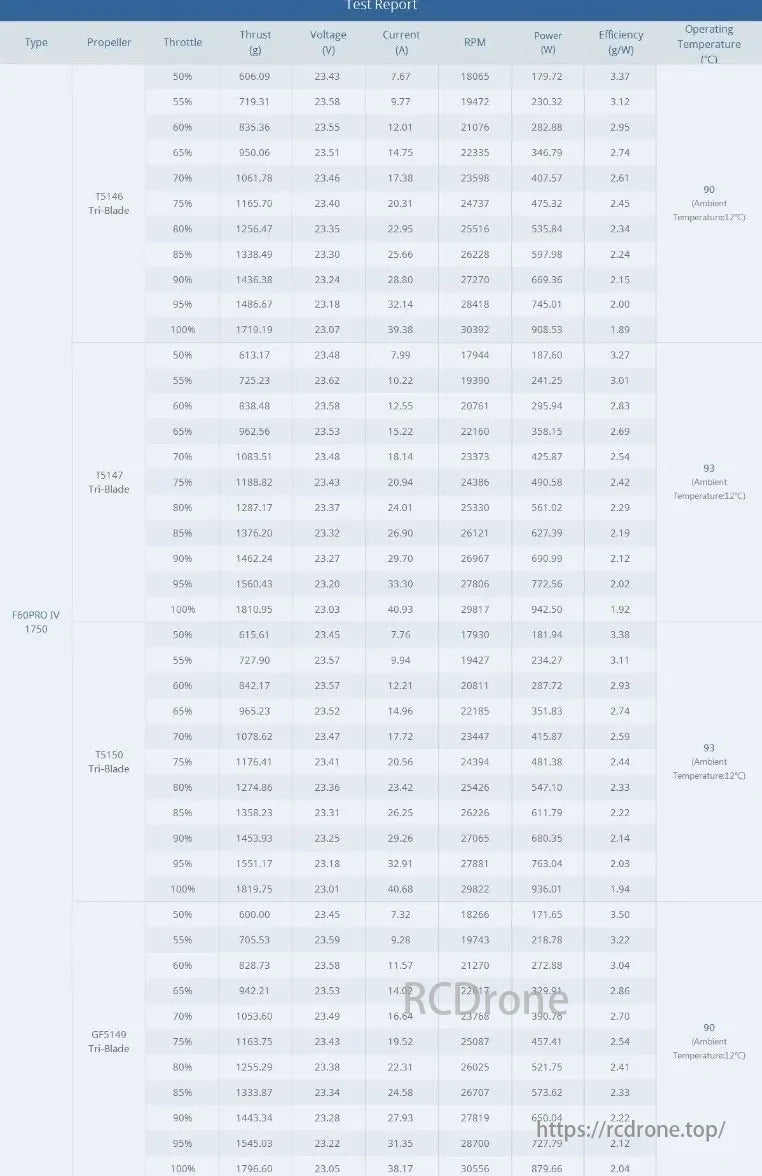

Test report for F60PRO IV 1750 motor with various propellers. Data includes throttle, thrust, voltage, current, RPM, power, efficiency, and operating temperature at different settings. Ambient temperature is 12°C.

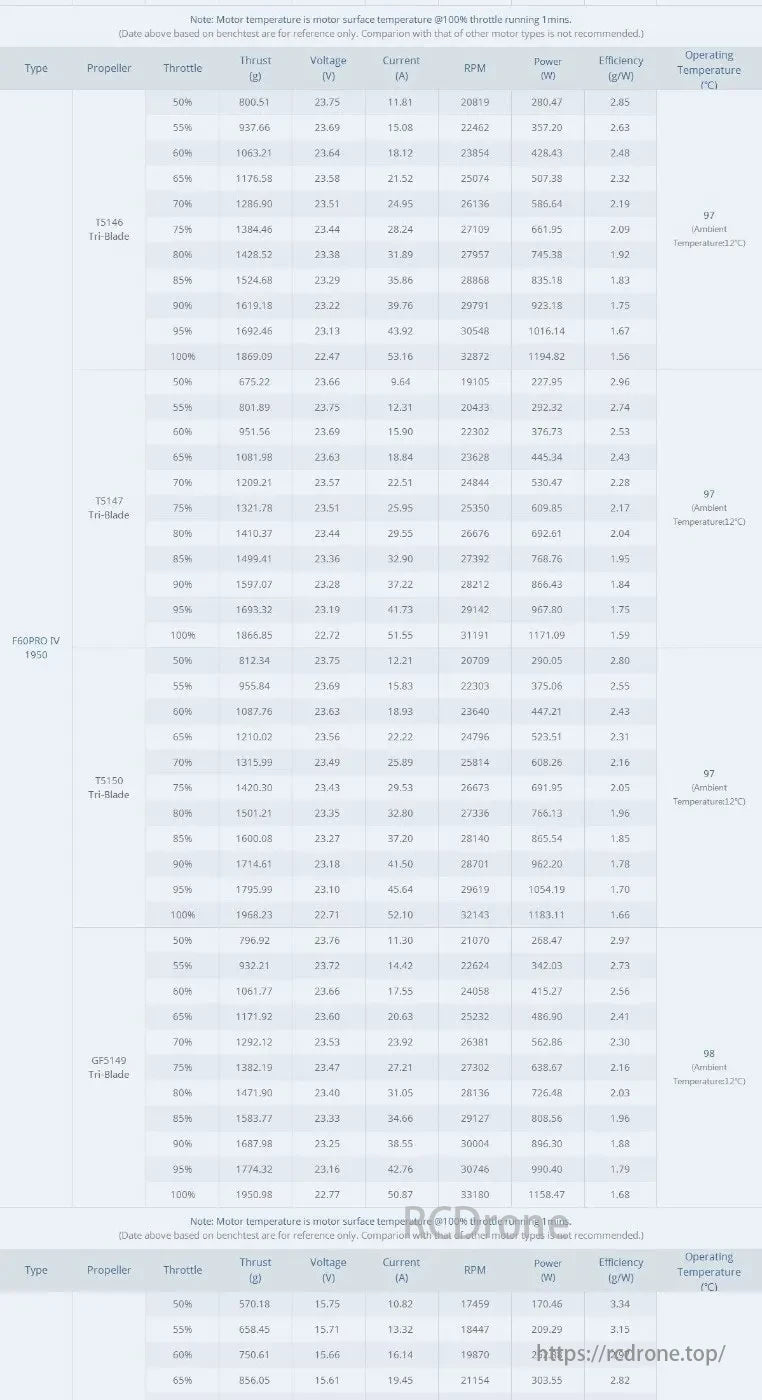

F60PRO IV 1950 motor performance data for various propellers (TS146, TS147, TS150, GFS149) at different throttle settings, including thrust, voltage, current, RPM, power, efficiency, and operating temperature. Ambient temp: 12°C.

F60PRO IV 2550 motor performance data for TS146, TS147, TS150, and GFS149 Tri-Blade props at various throttle levels. Includes motor temperature, ambient temp, and parts list.

Precautions for the first use of the motor:

Do not touch the coil with the screws used to fix the motor.

If you encounter resistance when locking the screw, do not forcefully screw into it, otherwise it will damage the thread of the screw hole and cause slippage, please try to replace a screw.

Make sure the ESC is normal and intact, if the ESC is faulty, it will not operate normally, if the MOS tube is damaged, it may burn the motor (coil) directly after power on.

T-MOTOR (and some brands) of FPV traversing motor (shaft) does not distinguish between positive and negative threads, use the relaxation nut to fix the paddle, do not need to match the positive and negative threads, locking the nut requires the use of tools (such as socket wrench) can not be locked with bare hands.

The direction of rotation of the motor can be set with the open source program BLHeliSuite 32 (the firmware supported by the ESC may be different) or by changing the three motor wires connected to the ESC by swapping the position of any two of the wires to change the direction of rotation.

Since the default PID parameters can not be suitable for all sizes of aircraft, if the motor overheating leads to coil burn, excluding the problem of excessive takeoff weight, please try to adjust the flight control PID parameters and filter parameters to reduce the burden on the motor.

If the damage is not serious, you can adjust the filter parameters to reduce the vibration sensitivity, if the damage is serious, please replace the bearings in time.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...