T-MOTOR MF1806 MF2009 MF2211 Polymer Folding propeller SPECIFICATIONS

Brand Name: T-MOTOR

Origin: Mainland China

Material: Carbon Fiber

Recommend Age: 14+y

RC Parts & Accs: Propellers

Size: MF2009

For Vehicle Type: Helicopters

Use: Vehicles & Remote Control Toys

Upgrade Parts/Accessories: motor

Remote Control Peripherals/Devices: ESC

Tool Supplies: Battery

Model Number: MF2009

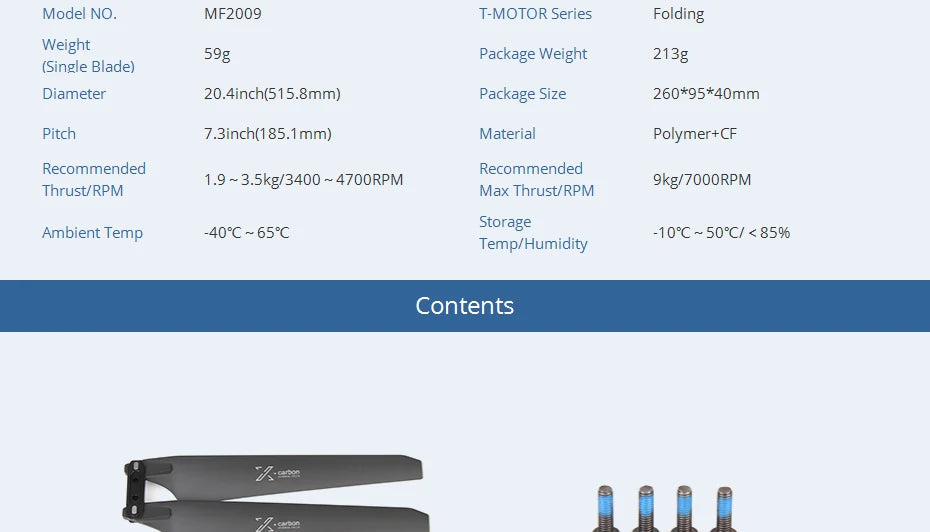

Model NO. MF2009 T-MOTOR Series Folding Weight Package Weight 213g (Single Blade) Diameter 20.4inch(515.8mm) Package Size 260*95*40mm Pitchn 7.3inch(1 85.1mm)

Warning: MF2009 Propeller (M3*10, Black Cup Head). Important Safety Precautions: 1. Avoid applying excessive force or stress onto the propellers. 2. Never disassemble or decompose the propeller, as this may lead to functional issues. 3. Do not use the propeller in hostile or adverse environments.

Carbon fiber propellers are designed with lightweight, high-density, and low-moment-of-inertia principles for exceptional performance.

Clear naming conventions enable easy selection of the ideal propeller. The 'MFZ09R' series offers a range of options specifically designed for multi-rotor applications.

Through continuous technology advancements, we have refined our injection molding process to create a unique hybrid blend of carbon fiber and polymer properties in our XCARBON propellers, resulting in optimized performance.

A 0.25mm precision mold is used to form the trailing edge surface, providing protection against airflow interference and UV rays. This design enables reduced prop drag and an optimized lift-to-drag ratio.

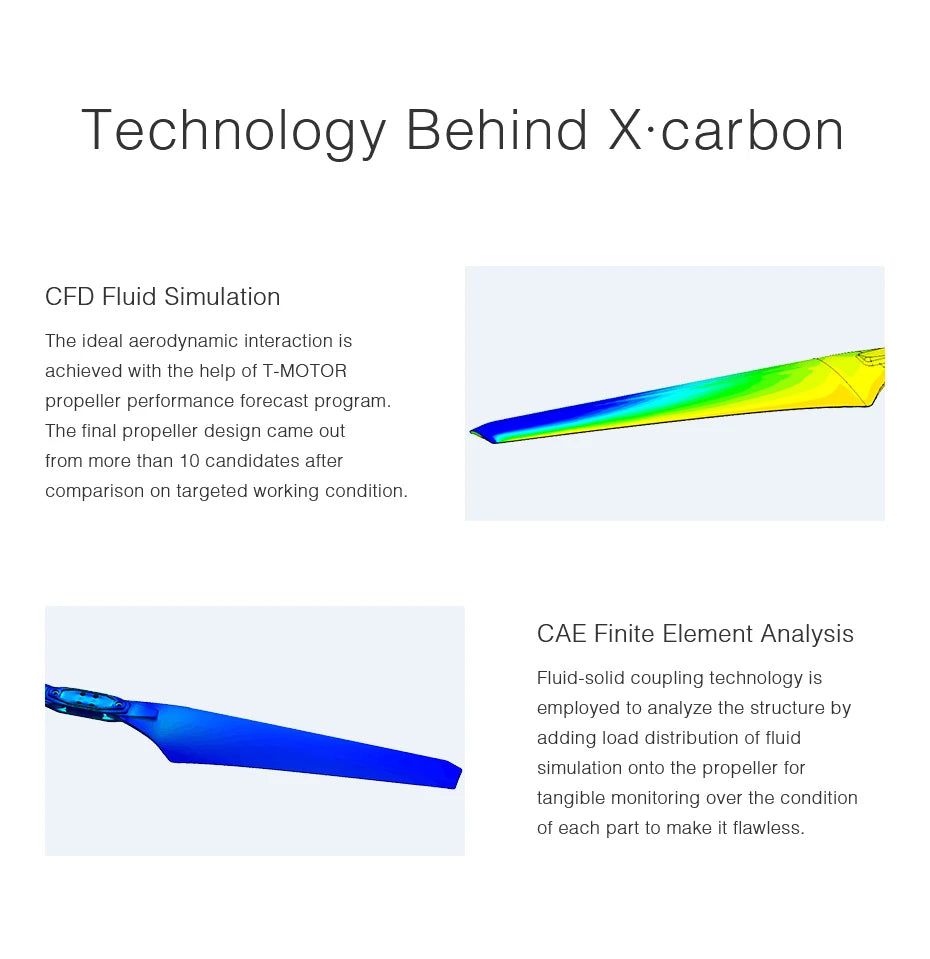

The optimal propeller design was selected from over 10 candidates following a comparative evaluation under targeted operating conditions. To further optimize the design, X-carbon CFD (Computational Fluid Dynamics) simulations were employed to analyze the structure by incorporating load distribution results from fluid simulation into the propeller's performance.

This propeller features innovative energy-snubber technology, which protects the motor from damage when the propeller is subjected to impacts. The unique design also absorbs shock energy upon impact, minimizing stress on the structure.

This propeller features a shaft design that shares the same steel material as the motor shaft, preventing spindles and screws from bending or warping. Additionally, the blades are crafted from 7075 aluminum alloy with anodizing treatment, providing a lightweight yet robust and rust-resistant construction.

T-MOTOR's R&D team has optimized the magnetic circuit design of their motors and Alpha ESCs to provide exceptional performance, ensuring fast response and a superior flying experience.

Superior texture tests were conducted to guarantee the highest level of craftsmanship and quality.

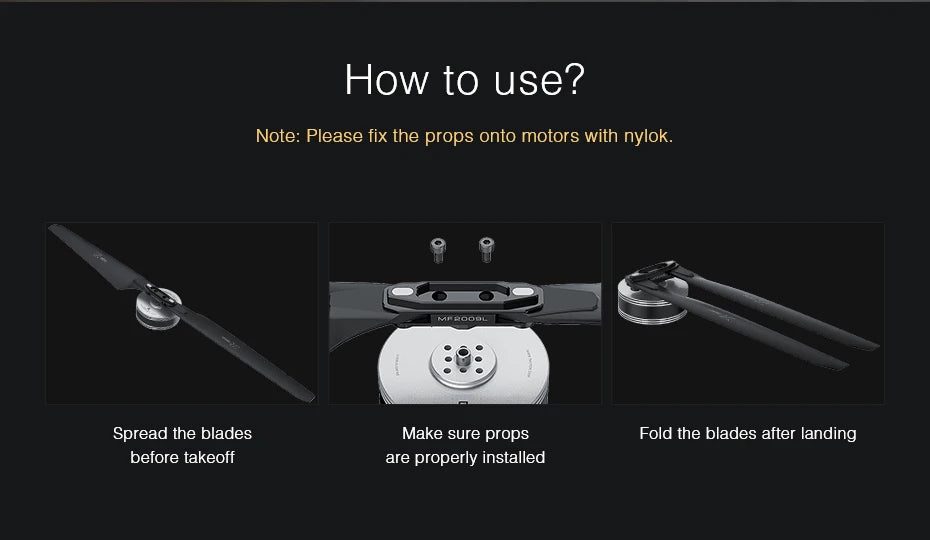

Install the propellers securely onto your motors using Nylock nuts, spreading the blades evenly to ensure proper installation before taking off.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...