Overview

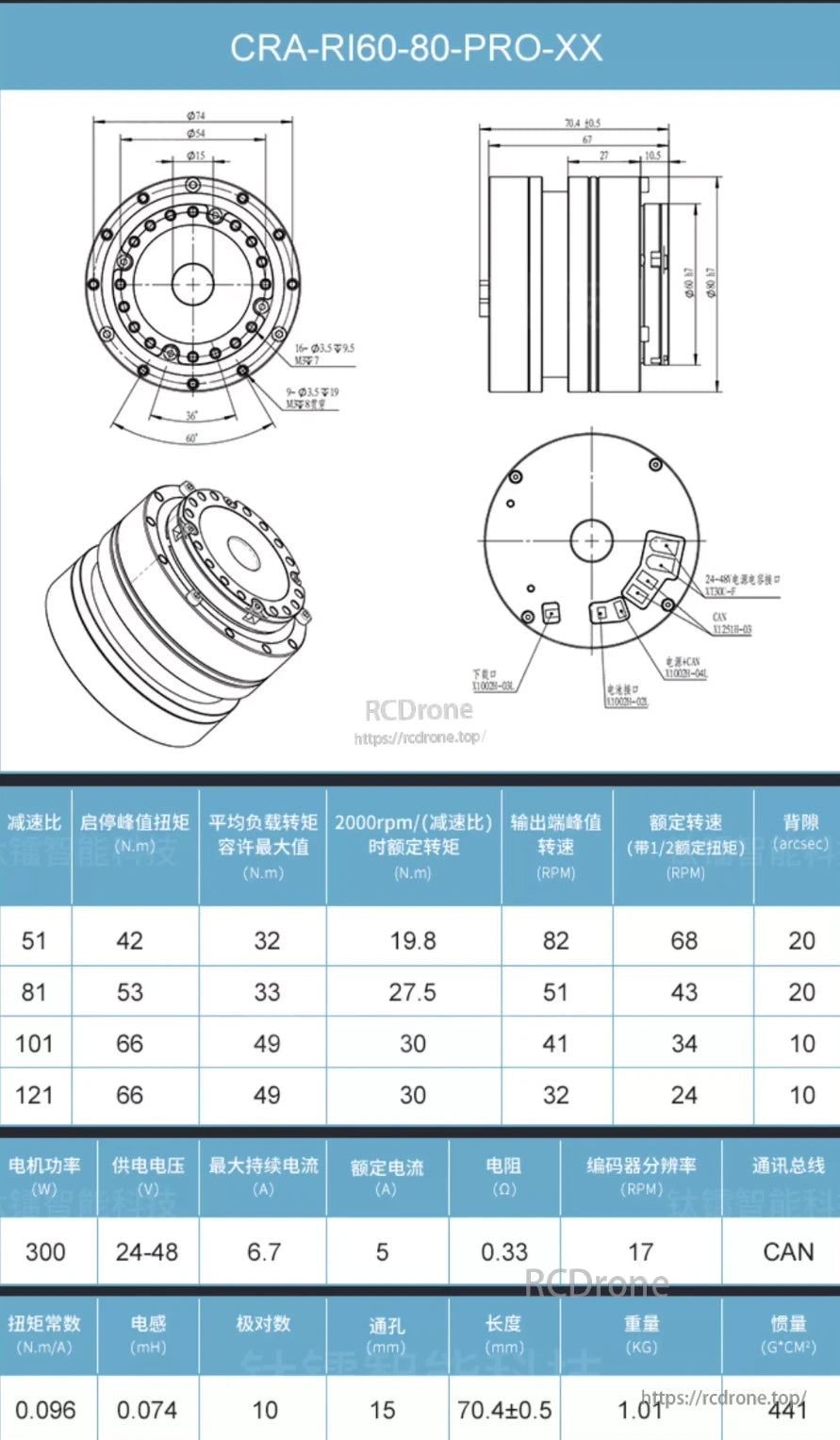

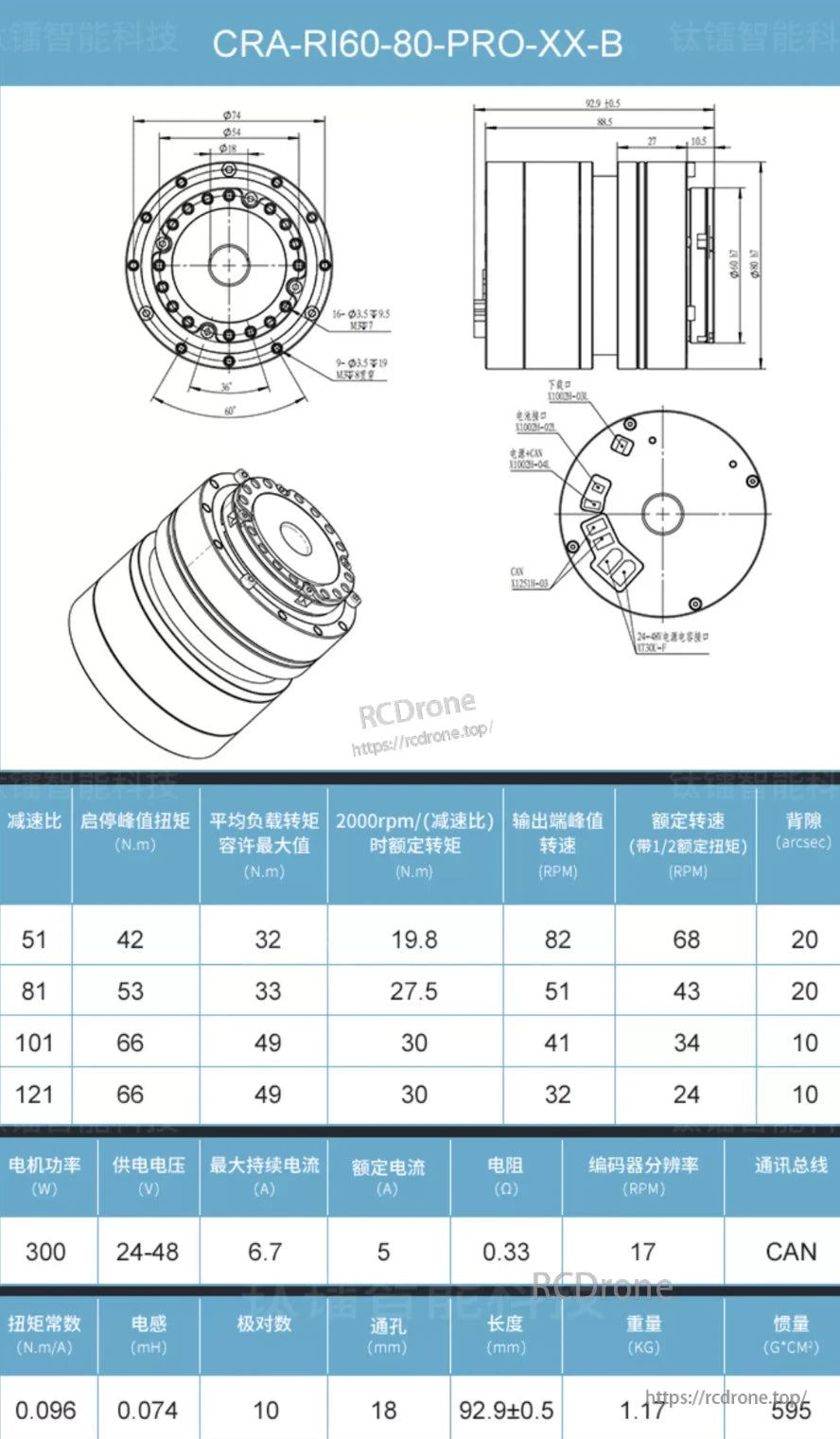

The Ti5 Robot CRA-RI60-80-PRO-XX is a compact, hollow-shaft integrated joint for humanoids, cobots and mobile manipulators. It combines an ultra-thin harmonic reducer, frameless torque motor, FOC servo drive, and absolute magnetic encoder in one module, delivering near-zero-backlash output, low noise, and high torque density. The joint supports CAN or EtherCAT, single or dual encoders, and an optional holding brake. Two lengths are available: the standard PRO-XX and the extended PRO-XX-B (longer body, higher rotor inertia, larger through-hole).

Key Features

-

All-in-one joint: harmonic reducer + torque motor + FOC driver + absolute encoder.

-

Near-zero backlash at the output; smooth low-speed control and low acoustic noise.

-

Hollow shaft design for cable/airway pass-through; multiple reduction ratios.

-

Absolute encoder, 17-bit, power-loss position memory; optional dual-encoder version.

-

Communication: CAN or EtherCAT selectable.

-

Power: 24–48 V, integrated driver, 300 W motor power class.

-

Optional holding brake; IP/waterproof & low-temperature customization available.

-

Application-ready for gimbals, humanoids, cobots, industrial equipment, patrol robots, and marine devices.

Specifications

Electrical & Control (shared by PRO-XX / PRO-XX-B)

-

Rated motor power: 300 W

-

Supply voltage: 24–48 V DC

-

Max continuous current: 6.7 A; rated current: 5 A

-

Phase resistance: 0.33 Ω

-

Torque constant: 0.096 N·m/A

-

Inductance: 0.074 mH

-

Pole pairs: 10

-

Encoder: 17-bit absolute; single/dual encoder options

-

Bus: CAN (standard) or EtherCAT (option)

Mechanical (hollow-shaft)

-

Through-hole (PRO-XX): Ø15 mm

-

Through-hole (PRO-XX-B): Ø18 mm

-

Length (PRO-XX): 70.4 ± 0.5 mm; weight ≈1.01 kg; rotor inertia ≈441 g·cm²

-

Length (PRO-XX-B): 92.9 ± 0.5 mm; weight ≈1.17 kg; rotor inertia ≈595 g·cm²

-

Mounting: front-face bolt circle (hollow output); harmonic reducer integrated

-

Options: holding brake; single/dual encoder; CAN/EtherCAT; waterproofing & low-temp package

Reducer options & performance (output side)

Backlash: as low as 10–20 arcsec depending on ratio.

| Reduction ratio | Start/stop peak torque (N·m) | Max avg load torque (N·m) | Rated torque at 2000 rpm/ratio (N·m) | Peak speed (rpm) | Rated speed @ ½ rated torque (rpm) | Backlash (arcsec) |

|---|---|---|---|---|---|---|

| 51:1 | 42 | 32 | 19.8 | 82 | 68 | 20 |

| 81:1 | 53 | 33 | 27.5 | 51 | 43 | 20 |

| 101:1 | 66 | 49 | 30 | 41 | 34 | 10 |

| 121:1 | 66 | 49 | 30 | 32 | 24 | 10 |

Notes:

• Data above is read from the product sheets for CRA-RI60-80-PRO-XX and PRO-XX-B.

• PRO-XX-B shares the same torque/speed table; it provides a larger through-hole and higher inertia with the longer body.

Applications

-

Humanoid & service robots: shoulder, elbow, hip, knee, ankle joints with high torque density.

-

Collaborative robot arms: precise low-backlash axes for smooth force control.

-

Gimbals & pan-tilt units: quiet, stable low-speed tracking with absolute position memory.

-

Industrial equipment & AGV/AMR manipulators: compact integrated actuation for tight spaces.

-

Power patrol and inspection robots; marine/shipboard devices (with waterproof option).

Details

CRA-RI60-80-PRO-XX robot joint module specifications: 300W motor, 24-48V input, CAN bus, 17 CPR encoder, 70.4mm length, 1.01kg weight, multiple gear ratios with torque and speed data provided.

CRA-RI60-80-PRO-XX-B robot joint module with 300W motor, 24-48V supply, CAN communication, 17 RPM encoder resolution, and multiple gear ratios. Key specs include torque, speed, current, and dimensions.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...