Overzicht

De RCDrone TDN045 Servo Elektrische Cilinder is een 45-serie servo lineaire actuator ontworpen voor nauwkeurige duw/trekbeweging in automatiseringsapparatuur. Het ondersteunt direct gekoppeld en 45° terugvouw montagestijlen, maakt gebruik van een precisie planetaire versnellingsbak voor hoog koppel en stabiele beweging, en is gebouwd rond een Ø12 mm kogelomloopspindel met 4 mm of 5 mm spoed opties. De stanguiteinde heeft een M12×1.25 interface, met externe of interne draad keuzes. Op basis van de verstrekte selectietabellen kan de actuator worden geconfigureerd voor een maximaal 1.00 kN nominale output (100 kg) en snelheden tot 250 mm/s afhankelijk van spoed, motor en overbrengingsverhouding.

Belangrijkste Kenmerken

-

Twee installatie stijlen: Directe koppeling en 45° terugvouw

-

Precisie planetaire tandwielkast: hoge nauwkeurigheid en hogere koppeloutput

-

Precisie kogelomloopspindel: beschreven als geïmporteerd, met ±2 “si” nauwkeurigheid (±0.02 mm) in de materialen

-

Opties voor de schroefdraad van de stang: externe schroefdraad of interne schroefdraad

-

Meerdere aandrijvingskeuzes: servomotor of stappenmotor configuraties met selecteerbare overbrengingsverhoudingen

Specificaties (van de geleverde afbeeldingen)

| Artikel | Spec |

|---|---|

| Serie | TDN045 |

| Actuatortype | Servo elektrische cilinder / lineaire actuator |

| Diameter van de kogelomloop | Ø12 mm |

| Opties voor de kogelomloop | 4 mm / 5 mm |

| Kogelomloopmoer | BSH-3.5 type genoteerd in tabel |

| Montagestijlen | Directe koppeling / 45° terugvouw |

| Stangdiameter (getoond) | 19 mm |

| Stang einddraad (getoond) | M12×1.25 |

| Behuizing sectie (getoond) | 45×45 mm |

Motor &en Versnellingsbak Opties (uit selectietabellen)

| Aandrijfoptie | Genomineerde snelheid | Genomineerd koppel | Opmerkingen |

|---|---|---|---|

| Servo motor 0.1 kW (40 frame genoteerd) | 3000 r/min | 0.32 N·m | Gebruikt in lead 4 / lead 5 tabellen |

| Servo motor 0.4 kW (60 frame genoteerd) | 3000 r/min | 1.27 N·m | Gebruikt in de tabel voor lead 4 / lead 5 |

| Stepper motor (maat 60, behuizing lengte 60) | 600 r/min | 0.8 N·m | Gebruikt in lead 4 / lead 5 tabellen |

| Planetaire versnellingsbakverhoudingen | 1 / 3 / 5 / 7 / 10 / 12 / 15 / 20 | 1-traps: 1–10, 2-traps: 12–20 |

Geclassificeerde output & snelheid selectie (uit de gegeven tabellen)

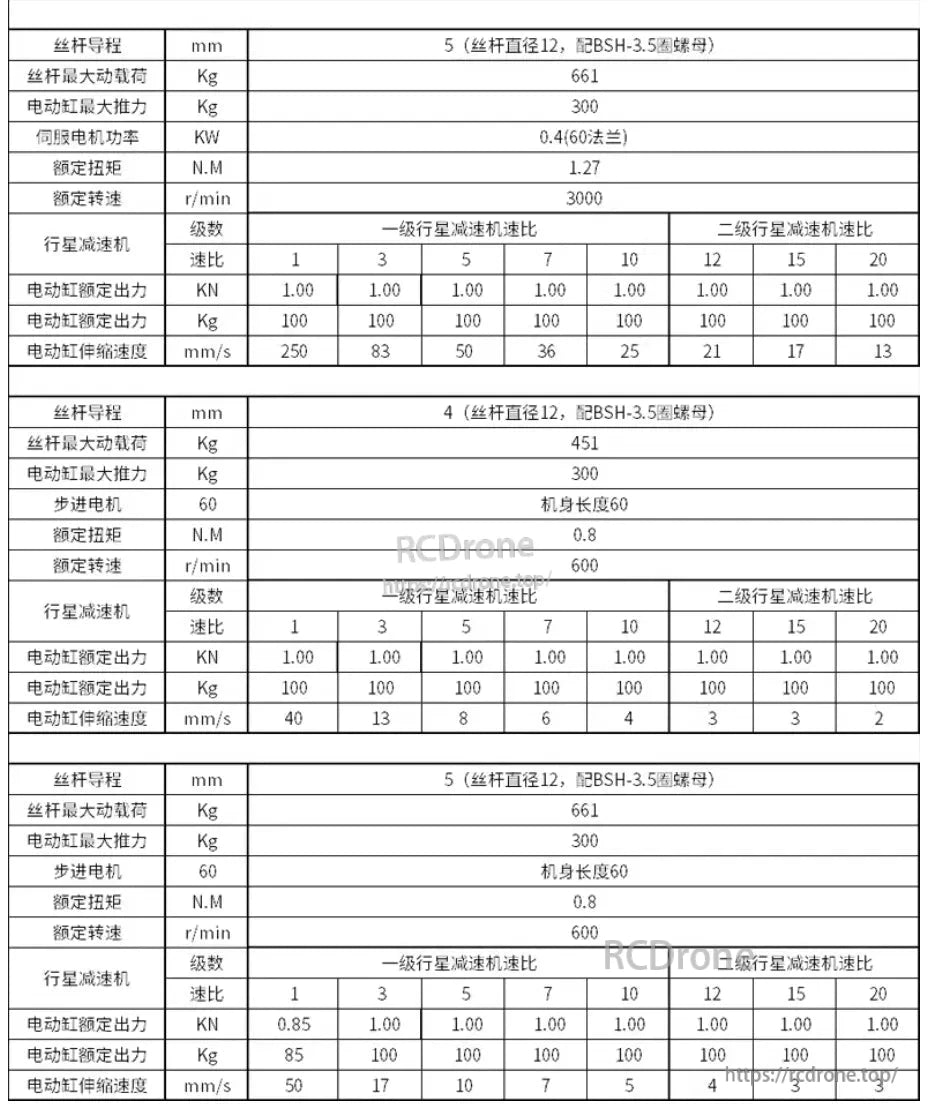

Lead 4 mm (Ø12 schroef)

-

Max dynamische belasting weergegeven: 451 kg

-

Max duwkracht weergegeven: 100 kg (tabelkop)

Servo 3000 t/min – Snelheid (mm/s) per verhouding

| Verhouding | 1 | 3 | 5 | 7 | 10 | 12 | 15 | 20 |

|---|---|---|---|---|---|---|---|---|

| Snelheid (mm/s) | 200 | 67 | 40 | 29 | 20 | 17 | 13 | 10 |

Beoordeelde output weergegeven (voorbeelden)

-

Servo 0.1 kW: 0.43 kN / 43 kg bij verhouding 1; 1.00 kN / 100 kg bij verhoudingen 3–20

-

Servo 0.4 kW: 1.00 kN / 100 kg bij verhoudingen 1–20

Stepper 600 r/min – Snelheid (mm/s) per verhouding

| Verhouding | 1 | 3 | 5 | 7 | 10 | 12 | 15 | 20 |

|---|---|---|---|---|---|---|---|---|

| Snelheid (mm/s) | 40 | 13 | 8 | 6 | 4 | 3 | 3 | 2 |

| Gegeven nominale output: 1.00 kN / 100 kg bij verhoudingen 1–20 |

Lead 5 mm (Ø12 schroef)

-

Max dynamische belasting weergegeven: 661 kg

-

Max duwkracht weergegeven: 300 kg (tabelkop)

Servo 3000 t/min – Snelheid (mm/s) per verhouding

| Verhouding | 1 | 3 | 5 | 7 | 10 | 12 | 15 | 20 |

|---|---|---|---|---|---|---|---|---|

| Snelheid (mm/s) | 250 | 83 | 50 | 36 | 25 | 21 | 17 | 13 |

Beoordeelde output weergegeven (voorbeelden)

-

Servo 0.1 kW: 0.34 kN / 34 kg bij verhouding 1; 1.00 kN / 100 kg bij verhoudingen 3–20

-

Servo 0.4 kW: 1.00 kN / 100 kg bij verhoudingen 1–20

Stepper 600 r/min – Snelheid (mm/s) per verhouding

| Verhouding | 1 | 3 | 5 | 7 | 10 | 12 | 15 | 20 |

|---|---|---|---|---|---|---|---|---|

| Snelheid (mm/s) | 50 | 17 | 10 | 7 | 5 | 4 | 3 | 3 |

| Gegeven nominale output: 0.85 kN / 85 kg bij verhouding 1; 1.00 kN / 100 kg bij verhoudingen 3–20 |

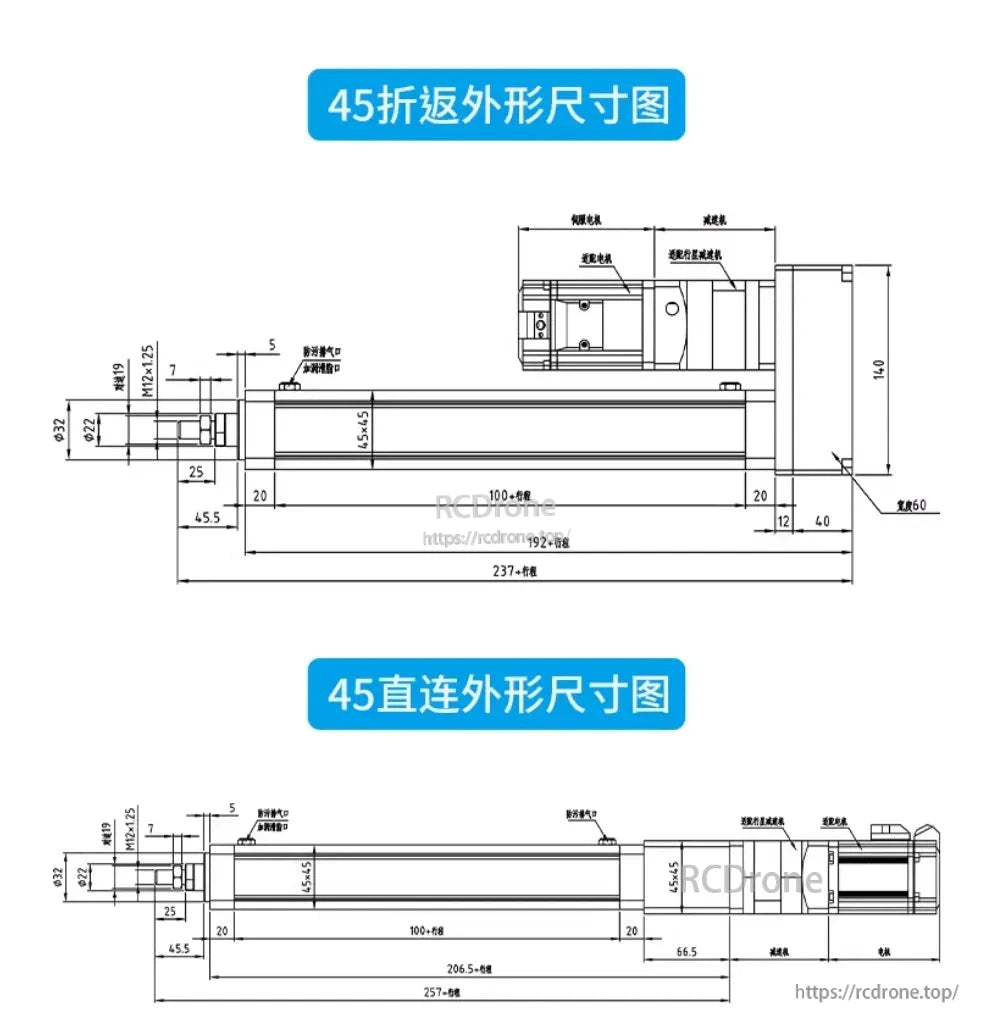

Afmetingen (volgens de tekeningen)

Stang-eind interface (getoond)

-

Draad: M12×1.25

-

Stangdiameter: 19 mm

-

Diameters weergegeven nabij de voorkant: Ø22, Ø32

-

Belangrijke vooroffsets weergegeven: 45.5 mm, 25 mm, 20 mm

-

Achter-/basisdetails weergegeven op de vouwtekening: 12 mm, 40 mm, basisbreedte 60 mm

-

Vouwtekening toont een totale hoogte dimensie: 140 mm

Algemene lengtevormule (afhankelijk van de slag, mm)

| Versie | Sleutellengte aanduidingen (mm) |

|---|---|

| 45° vouw | 100 + slag, 192 + slag, 237 + slag |

| Directe koppeling | 100 + slag, 206.5 + slag, 257 + slag |

Typische Toepassingen

-

Geautomatiseerde bevestigingen, klemmen, duwen/trekken en positioneren

-

Persen, assembleren, voeden, overdragen en pick-and-place hulpasen

-

Testbanken die herhaalbare lineaire beweging vereisen

-

Apparatuurupgrades ter vervanging van pneumatische cilinders waar programmeerbare beweging nodig is

Aanpassing &en Ondersteuning

Heeft u een specifieke slag, overbrengingsverhouding, motortype, of draad einde nodig voor uw project? Neem contact op support@rcdrone.top met uw doelbelasting, snelheid en slagvereisten.

Wat is inbegrepen

-

1× RCDrone TDN045 Servo Elektrische Cilinder / Lineaire Actuator (directe of 45° opvouwconfiguratie, per bestelling)

Opmerking:

Dit is een professionele, configuratie-gebaseerde servo elektrische cilinder. Bevestig alstublieft uw vereiste slag, belasting/duwkracht, snelheid, montagestijl en motor/tandwielverhouding met ons team voordat u bestelt (of onmiddellijk na aankoop) om de juiste bouw en compatibiliteit te waarborgen.

Afmeting

Technische diagrammen tonen de afmetingen van de servo met 45 graden terugkeer en directe aansluiting, met metingen voor mechanische integratie en assemblagespecificaties.

Selectietabel voor de TDN045 servo elektrische cilinder met stangloop, maximale belasting, duwkracht, motorvermogen, koppel, snelheid en planetaire overbrengingsverhoudingen over configuraties.

Technische specificaties voor servomodellen met verschillende schroefassen, laadcapaciteiten, motortypes, koppel, snelheid en planetaire overbrengingsverhoudingen. Belangrijke gegevens omvatten maximale dynamische belasting, duwkracht, RPM en slag snelheden over configuraties.

Related Collections

Verken meer drones en accessoires

-

Camera Drone

Onze Camera Drone Collectie biedt een breed scala aan merken, waaronder FIMI,...

-

FPV -drone

Ontdek onze complete FPV-dronecollectie, met race-, freestyle-, longrange-, cinewhoop- en tandenstokerdrones in...

-

Drone -accessoires

Ontdek een breed scala aan drone-accessoires om de vliegprestaties te verbeteren, de...