-

AGFRC B53DHS - 24KG Digital High Torque Speed Titanium Gear Programmable HV Steering Servo For 1/12 1/10 RC Car Trucks RC Model

Regular price From $36.83 USDRegular priceUnit price per -

Anniversary Edition AGFRC A06CLS V2 -3.0kg Titanium Gear 0.052Sec 7g Fast Programmable Micro Servo Mini Car GLR GLA MRZ Airplane

Regular price From $21.81 USDRegular priceUnit price per -

AGFRC A80BHMW V2 - Steel Gears 40KG Programmable Waterproof BLS RC Steering Servo For 1/10 Scale Car Crawler Buggy Truck Off-Road

Regular price From $99.72 USDRegular priceUnit price per -

AGFRC A81BHP - 23KG Super Speed Steel Gears HV Brushless Programmable Standard Steering Servo For 1/8 RC Truck Car Boat Aircraft

Regular price From $39.66 USDRegular priceUnit price per -

AGFRC SA30BHM - 11.5KG HV High Speed Programmable Motor Brushless Mini Smart Steering RC Servo for 1/12 1/16 RC Car Rock Crawler

Regular price From $40.64 USDRegular priceUnit price per -

AGFRC A06CHR - Metal Gears 3kg High Torque Coreless Motor Micro Wing Servo Ideal For Small Size Airplane F3P GLD Glider Sailplane

Regular price From $74.81 USDRegular priceUnit price per -

AGFRC A80BHX-H - 8.4V 30KG Programmable Helicopter Cyclic Servo High Torque High Voltage Brushless Digital Motor For RC Helicopter

Regular price From $12.90 USDRegular priceUnit price per -

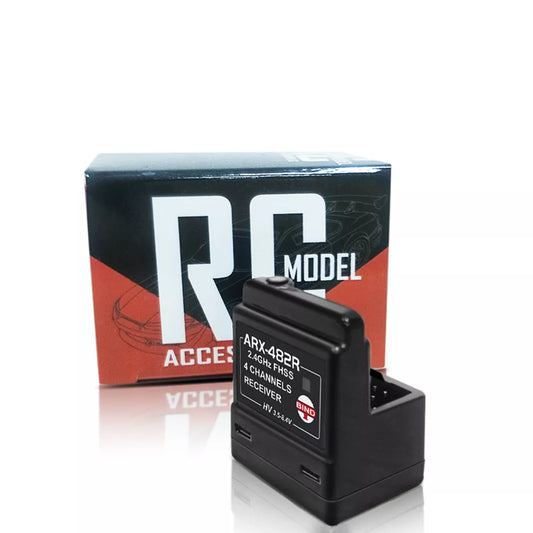

AGFRC ARX-482R 4CH FHSS Internal Antenna Receiver Compatible with FH3/FH4T For remote control M12 M11X EXZES X MT-4 GEMINI X MT-S MT-4

Regular price $69.76 USDRegular priceUnit price per -

AGFRC C02CLS - 0.11kg / 0.06sec Plastic Gear 180 Degree 2.2g Sub-Micro Nano Digital Servo For Micro Parkflyers RC Plane Helicopter

Regular price From $14.31 USDRegular priceUnit price per -

AGFRC A06CLS V2 Black Aluminum Case - 6g Titanium Gear 3KG Micro Digital Coreless Servo For Mini Z Car GLR GLA MRZ Airplane RC F3P

Regular price From $73.03 USDRegular priceUnit price per -

AGFRC A06CLS V2 - 3.0KG 0.052Sec CNC 20T HV 7g Titanium Gear Super Fast Programmable Micro Servo for Mini Car GLR GLA MRZ Airplane

Regular price From $78.46 USDRegular priceUnit price per -

AGFRC A06CLS V2 - 3.0KG 6g Titanium Gear Super Fast Programmable Micro Servo For 1/18 1/24 1/27 1/28 Mini Car GLR GLA MRZ Airplane

Regular price From $78.86 USDRegular priceUnit price per -

AGFRC A11CLS V3 - Micro Digital servo Super Speed 1.4KG Coreless Programmable motor Servo For 1/28 1/27 1/24 1/18 Mini Z Cars Boat

Regular price From $11.61 USDRegular priceUnit price per -

AGFRC A280BHMW A280BHLW 78KG 100KG 5th Scale HV High Torque WP Brushless RC Racing Servo For 1/5 Large Aircraft Car Boat RC Mode

Regular price From $316.35 USDRegular priceUnit price per -

AGFRC B13DLM V2 - 4.5KG High Torque 13g Titanium Metal Gear 6.0V Digital Micro Servo for 1/14 1/24 1/28 Mini RC Car Crawler Planes

Regular price From $30.13 USDRegular priceUnit price per -

AGFRC GY04M V3.5(Purple) Aluminum Case - High Stability Mini Dual Gain Steering Tuned Gyro For Mini-Z Car Drift F1 Touring Offroad

Regular price $53.93 USDRegular priceUnit price per -

AGFRC B53BHP V2 - Brushless RC Servo HV 20KG Upgraded Steel Gear Programmable Digital Standard Servo for 1/10 RC Car Boat Crawler

Regular price From $79.09 USDRegular priceUnit price per -

AGFRC A80BHSW V2 - 36KG Waterproof High Torque Hi-Speed Brushless RC Steering Servo Motor For 1/10 Off Road RC Car Truck Airplane

Regular price From $112.12 USDRegular priceUnit price per -

AGFRC C1.5CLS PRO Upgrade 9mm High Speed 1.5g Ultra Micro Digital Linear Servo For DIY Indoor 3D Flight Printer Helicoper Plane

Regular price From $16.04 USDRegular priceUnit price per -

AGFRC GY01 CNC Aluminum Case High Stability Control Easy Gain Tuned Adjustable Steering Rated Gyro Part for RC Drift Car F1 Car

Regular price From $45.99 USDRegular priceUnit price per -

AGFRC A86BUMW - Waterproof Metal Gear 4S Lipo 16.8V 66KG High Torque Brushless Digital Steering Servo for RC Crawler Cars Truggy

Regular price From $43.57 USDRegular priceUnit price per -

Anniversary Edition AGFRC A280BHMW - 78KG High Torque Waterproof Brushless For 1/5 Scale RC Racing Servo Large Aircraft Car Boat

Regular price From $312.62 USDRegular priceUnit price per -

AGFRC A80BHMF - 40kg Aircraft Servo Programmable Steel + Titanium Gear Digital Brushless Standard Servo For 30-200CC RC Airplane

Regular price From $105.16 USDRegular priceUnit price per -

AGFRC CAP3000C Aluminum Case 3000uF DC 16V HV Super Power Capacitor Box For 1/8 1/10 1/12 RC Car Models Crawler Trucks Buggies

Regular price $24.91 USDRegular priceUnit price per -

AGFRC A75BUMW - 4S 16.8V 62KG Super Torque HV Programmable Waterproof Brushless RC Servo For 1/8 1/10 RC Car Crawler Buggy Truck

Regular price From $117.33 USDRegular priceUnit price per -

AGFRC A11CLS V3 Anniversary Edition - Programmable Super Speed 1.4KG Micro Coreless Servo Gyro V3.5 Kit For 1/24 1/18 Mini Z Car

Regular price From $38.10 USDRegular priceUnit price per -

AGFRC A80BHX-H - 30KG 0.038Sec 25T Aluminum Case High Torque HV Brushless Cyclic Servo For 570-800 Class Helicopter Swash Plate

Regular price From $110.94 USDRegular priceUnit price per -

AGFRC Servo A80BHSF - 36KG HV Fast Speed High Torque Brushless Standard Programmable Aircraft Servo for 30-200CC RC Airplane

Regular price From $105.16 USDRegular priceUnit price per -

AGFRC A280BHMW - 1/5 Scale Giant Servo 78KG High Torque Steel Gears Programmable Digital Brushless RC Racing Servo For Crawler

Regular price From $349.93 USDRegular priceUnit price per -

AGFRC CNP2000C 16V 2000uF Aluminum Case Non Polarity Low Impedance Mini Capacitor Box For Mini Scale Car Touring Car Drifter

Regular price $44.71 USDRegular priceUnit price per -

AGFRC A73CHLW Limit Edition - 32KG Digital Coreless High Torque 1/10 HV Programmable Waterproof Steering Servo for RC Car Boat

Regular price From $31.83 USDRegular priceUnit price per -

AGFRC B53DHN - Fast Speed 20KG Titanium Gear HV Programmable Digital DC Servo Motor for RC Car Part airplane Robot Boat Models

Regular price From $47.94 USDRegular priceUnit price per -

AGFRC A11CLS V3 - Racing Drift Kit Gyro Programmable Servo Super Speed 1.4KG Micro Servo For 1/28 1/24 1/18 RC Mini Z D Q Cars

Regular price From $11.73 USDRegular priceUnit price per -

AGFRC A72BHX - 26KG High Torque Fast Speed HV Brushless Metal Gear Digital Steering Servo Motor For 1/10 RC Car Crawler Buggy

Regular price From $20.11 USDRegular priceUnit price per -

AGFRC Short Cable A06CLS V2 15T Spline MG 3.0KG 0.052Sec Programmable Coleress RC 7g Micro Servo for Mini Car GLR GLA MRZ Airplane

Regular price From $78.86 USDRegular priceUnit price per -

AGFRC A73BHLW V2 Servo - HV 40KG High Torque Brushless Waterproof Digital Standard Servo For 1/10 RC Rock Crawler Buggy Car Boat Truck

Regular price From $64.77 USDRegular priceUnit price per