-

Kingmax KM1203MD - 4.8V~8.4V 6kg-10.5kg.cm DC 20g digital metal gears mini servo for 450-480 class helicopter swashplate 30E fixed-wing

Regular price $33.83 USDRegular priceUnit price per -

DSServo DS3218 Digital Servo - 20KG 180 270 Degree High Speed Servo IP66 Metal Gear DS3218 PRO RC Servo for 1/8 1/10 Scale RC Cars

Regular price From $14.81 USDRegular priceUnit price per -

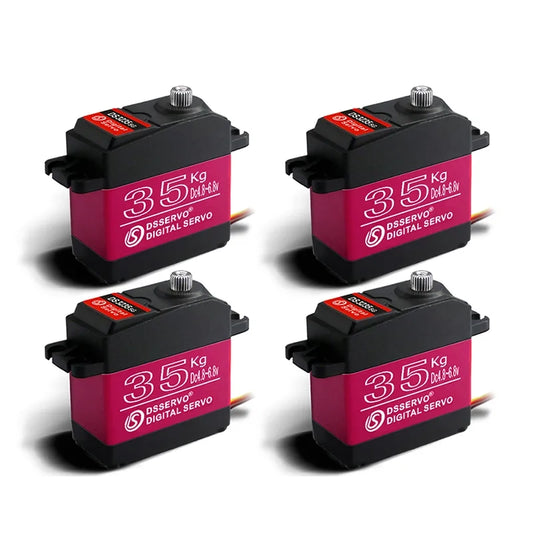

4X DSServo Waterproof Servo 20Kg 25Kg 30Kg 35Kg 40Kg High Speed servo Pro Metal Gear Digital Servo Baja Servo For 1/8 1/10 Scale RC Cars

Regular price From $45.31 USDRegular priceUnit price per -

JX Servo PDI-HV5932MG - 8.4V 32KG Large Torque 120 180 360 degree High Voltage Digital Standard Servo For RC Car Boat Robot Parts

Regular price From $33.44 USDRegular priceUnit price per -

GXServo HS-1005SGT 200KG Brushless Servo - All Metal Digital High-voltage Robot Arm RC Car Drone Servo

Regular price $279.00 USDRegular priceUnit price per -

4PCS DSServo 150KG 12V DS51150 Digital Servo 180/270 Degree IP66 with 18T Servo Arm Full Metal Gear Servo Motor for RC Car Robot

Regular price $115.26 USDRegular priceUnit price per -

DSServo Waterproof Servo 20Kg 25Kg 30Kg 35Kg 40Kg High Speed servo Metal Gear Digital Servo RC Baja Servo For 1/8 1/10 Scale RC Cars

Regular price From $15.46 USDRegular priceUnit price per -

DSServo DS3240 40Kg Waterproof Servo - High Speed servo Pro Metal Gear Digital Servo RC Baja Servo For 1/8 1/10 Scale RC Cars

Regular price $16.49 USDRegular priceUnit price per -

DSServo DS51150 - 12V 150Kg baja 5B 1/5 high torque Digital Servo for Redcat HPI Baja 5B SS RC servo Car compatible SAVOX-0236

Regular price $36.47 USDRegular priceUnit price per -

EMAX ES09MD - 13.5G HV Metal Gear Digital Servo 21T Servo for RC Car Truck Robot Upgrade Parts

Regular price From $35.34 USDRegular priceUnit price per -

JX Servo PDI-1109MG - 9g 2.5kg Metal Gear digital Core Servo For Fixed Wing 1/18 RC Car Boat Robot Arm Helicopter

Regular price From $9.90 USDRegular priceUnit price per -

Original JX Digital Servo 17g Metal Gear PDI-1181MG For RC helicopter/ RC Car/ RC Boat/ RC Airplane

Regular price From $16.03 USDRegular priceUnit price per -

Mayatech 1258TG V3 20KG Servo - Waterproof and High Torque Metal Tooth Actuator Digital steering gear servo can to parabolic 1268SG

Regular price From $27.74 USDRegular priceUnit price per -

Deao 20kg 25kg 30kg 35kg Servo - 180° 270° High Torque Digital Servo Waterproof Metal Gear 25t Rc Truck Mechanical Arm

Regular price From $12.55 USDRegular priceUnit price per -

4X Coreless servo 25kg 35KG high speed servo pro digital and Stainless Steel gear servo arduino servo for Robotic DIY,RC car

Regular price From $85.42 USDRegular priceUnit price per -

4X DSServo baja 5B servo 1/5 DSServo 60Kg 80Kg 150Kg high torque Digital Servo for Redcat HPI Baja 5B SS RC servo Car compatible SAVOX-0236

Regular price From $17.73 USDRegular priceUnit price per -

DSServo DS3225 update servo - 7.4V 25KG full metal gear digital servo baja servo Waterproof servo for baja cars

Regular price From $17.88 USDRegular priceUnit price per -

DSServo DS5180 - 80Kg high torque Digital Servo for Redcat HPI Baja 5B SS RC servo Car compatible SAVOX-0236

Regular price $25.36 USDRegular priceUnit price per -

Dsservo DS3218 20KG DS3225 25KG DS3235 35KG Waterproof Servo 180/270 Degree for 1/8 1/10 1/12 RC Cars Metal Gear Digital Servo

Regular price From $15.16 USDRegular priceUnit price per -

AGFRC B53DHS - 24KG Digital High Torque Speed Titanium Gear Programmable HV Steering Servo For 1/12 1/10 RC Car Trucks RC Model

Regular price From $36.83 USDRegular priceUnit price per -

JX Servo CLS6336HV CLS6322HV 35kg 21KG Torque High Voltage High-precision Metal Coreless Digital Servo For RC Helicopter Car

Regular price From $37.08 USDRegular priceUnit price per -

JX Servo PDI-6121MG - 6V 21KG 0.13sec 120° High Precision Metal Gear Digital Coreless Standard Servo For RC Model

Regular price From $30.06 USDRegular priceUnit price per -

FEETECH FB5317M - 8.4V 15kg/17kg 360 Degree Continuous Rotation Analog Feedback with Magnetic Encoder Digital Servo For Robot RC Car

Regular price From $20.10 USDRegular priceUnit price per -

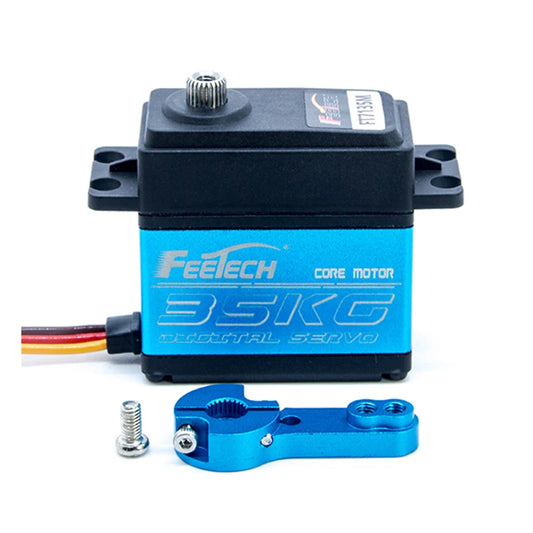

Feetech FT7135M - 35KG 180 Degree Digital Servo Metal Gear Waterproof Servo DS3235 Baja Servo Metal Arm for 1/8 1/10 1/12 RC Cars

Regular price $19.05 USDRegular priceUnit price per -

OCServo OCS-D2107 - 8.4V21kg.cm 0.07S/60° Digital Mid Servo High Vottage High Torque Coreless servo

Regular price From $44.91 USDRegular priceUnit price per -

Futaba S3150 Slim Digital Metal Gear Micro Servo 7kg/cm

Regular price $90.00 USDRegular priceUnit price per -

JX PDI-HV2060MG 60KG High Torque 180 Digital Servo For RC Model Helicopter Robot Parts Accessories

Regular price $54.34 USDRegular priceUnit price per -

MG90S 9g Metal Gear Mini Rc Servo Upgraded SG90 Digital Micro Servos for RC Fixed wing Aircraft model Helicopter Car Toy

Regular price From $45.20 USDRegular priceUnit price per -

2PCS DSServo RDS3225 Servo - 25kg metal gear digital servo arduino servo for Makeflyeasy Fighter RC Airplane Makeflyeasy Freeman

Regular price $66.00 USDRegular priceUnit price per -

MKS Servos HS75 Servos Motor Metal Gear High-Voltage Digital 55.5 oz-in Torque, 7.9 g — Wing/Aileron

Regular price $129.00 USDRegular priceUnit price per -

MKS DS1220 Titanium Gear Ultra High Torque Standard Digital Servos Motor

Regular price $149.00 USDRegular priceUnit price per -

MKS HV1250 7.4V Titanium Gear Coreless HV Digital Servos Motor for 1/10 RC Buggy/Heli

Regular price $168.00 USDRegular priceUnit price per -

MKS HV1220 Titanium Gear Ultra High Torque Standard Digital Servos Motor (High Voltage)

Regular price $169.00 USDRegular priceUnit price per -

MKS X6 HBL575SL Brushless Titanium Gear Low Profile Digital Servo Servos Motor

Regular price $233.00 USDRegular priceUnit price per -

MKS X6 HBL575 Brushless Titanium Gear High Speed Digital Servo (High Voltage)

Regular price $299.00 USDRegular priceUnit price per -

MKS X6 HBL599SL 8.4V High Torque Digital Brushless Servos Motor Metal Gear

Regular price $249.00 USDRegular priceUnit price per