T-motor MF3016 MF2211 Polymer 30 inch Folding propeller SPECIFICATIONS

Brand Name: T-MOTOR

Origin: Mainland China

Material: Carbon Fiber

Recommend Age: 14+y

RC Parts & Accs: Propellers

Size: 34"

For Vehicle Type: Helicopters

Use: Vehicles & Remote Control Toys

Upgrade Parts/Accessories: motor

Remote Control Peripherals/Devices: ESC

Tool Supplies: Battery

Model Number: MF3422

Easy Choice Clear naming convention lets you choose the most suitable propeller easily . MF1604R Multi (Props for multi-rotors) CCW (L for CW) (Max. thrust provided by the prop)

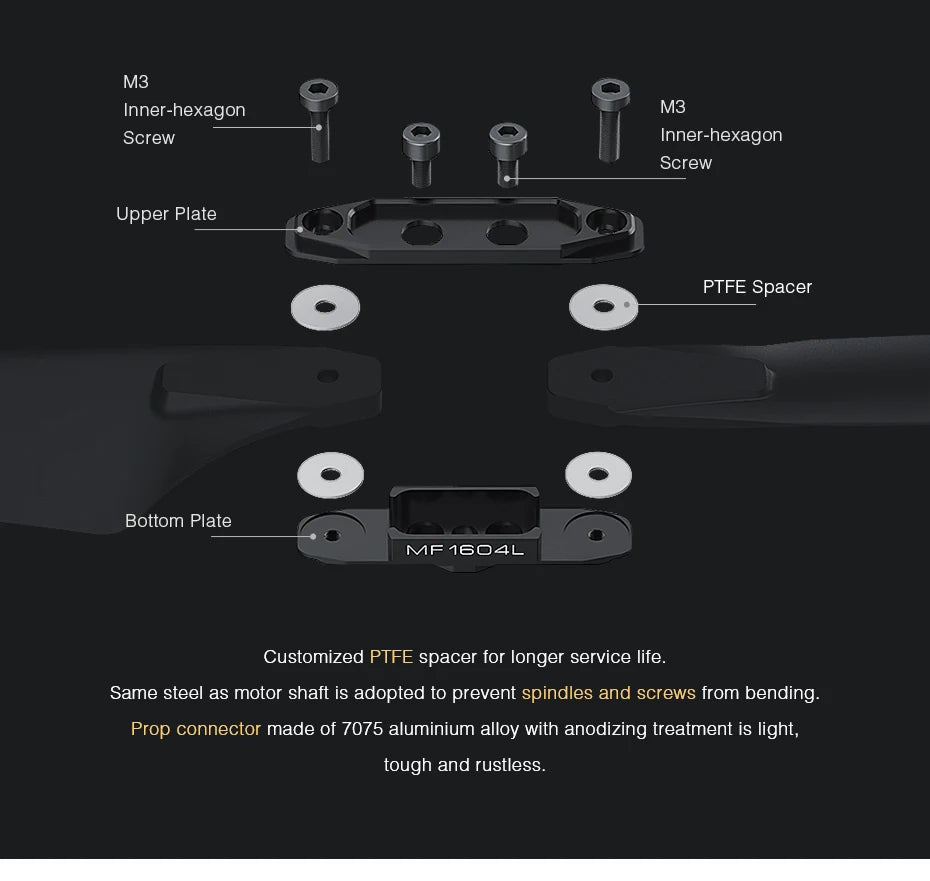

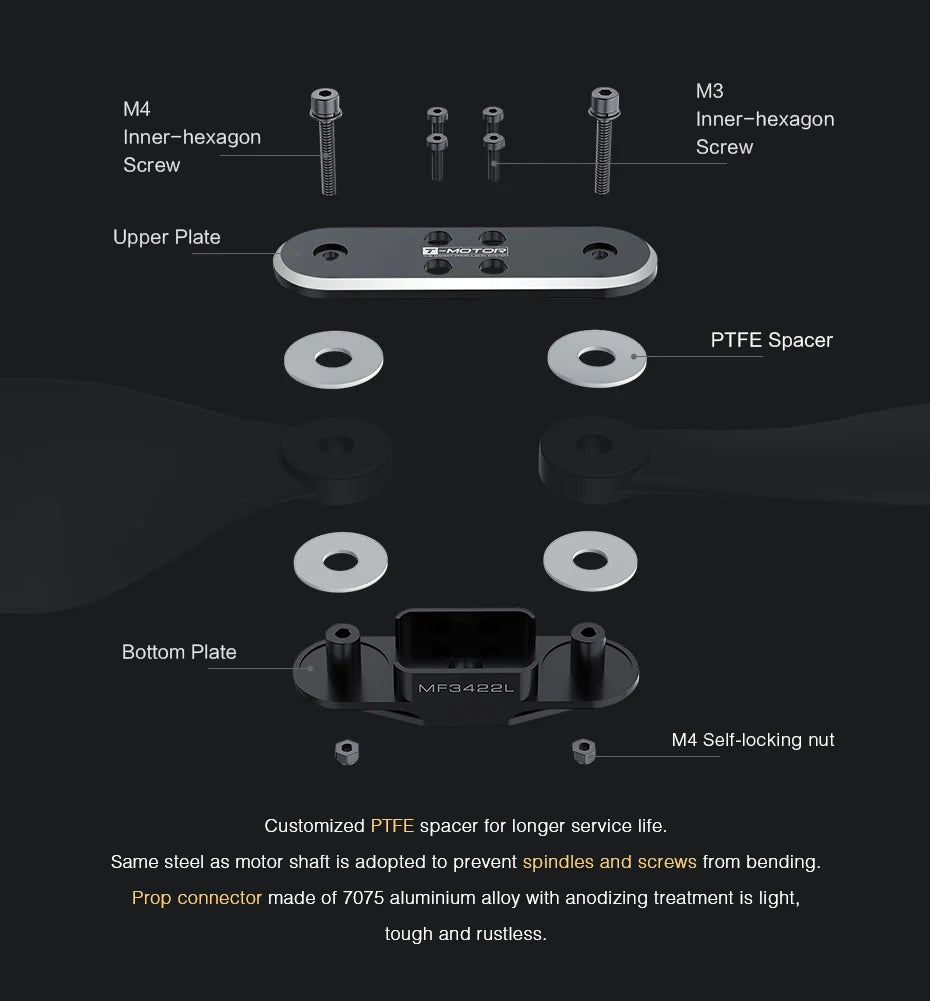

The PTFE spacers are made from high-strength 7075 aluminum alloy and feature an anodized finish, providing a lightweight, durable, and corrosion-resistant solution.

With the T-Motor MF3016/MF2211 series, you can easily select the most suitable propeller for your multi-rotor drone. This product line includes the MF3016R, designed specifically for multi-rotors, with a clockwise (CW) or counter-clockwise (CCW) rotation option. It provides a maximum thrust of 6kg.

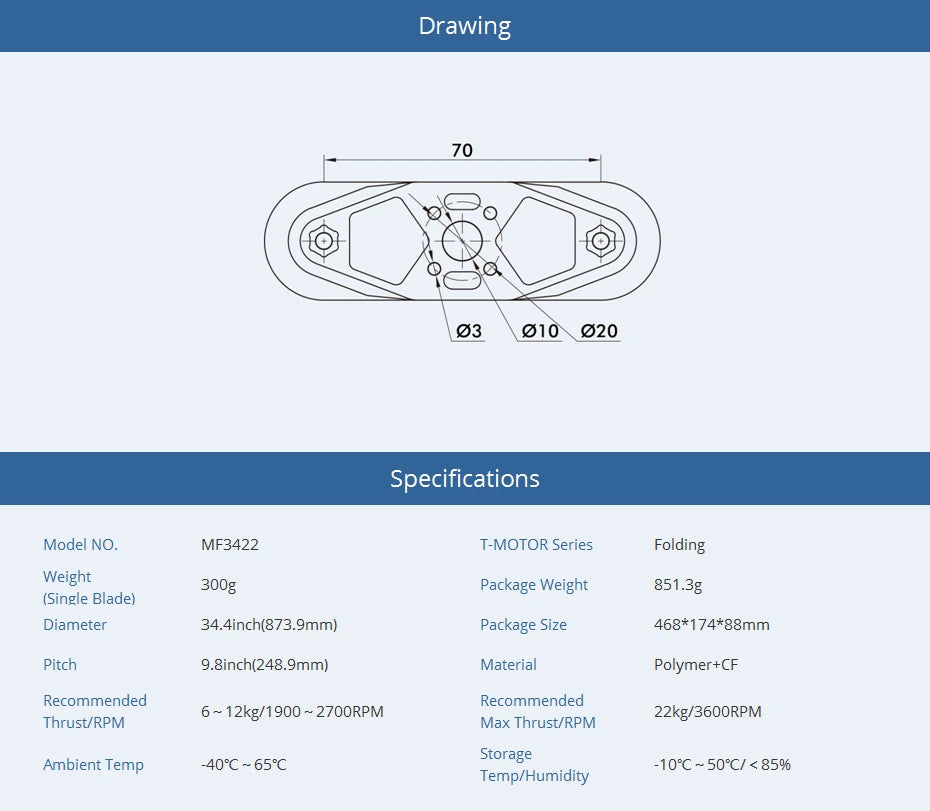

Specifications Model NO MF3422 T-MOTOR Series Weight 300g Weight 851.3g (Single Blade) Diameter 34.4inch(873.9mm) Size 468*174*88mm Pitch 9.8inch(248.9mm) Material Polymer+CF Recommended Recommended 6 12kg/1900 2700RPM 22kg/3600RPM ThrustRPM Max Thrust/RPM Storage Ambient Temp 40C 65'C 10FC 50'CI

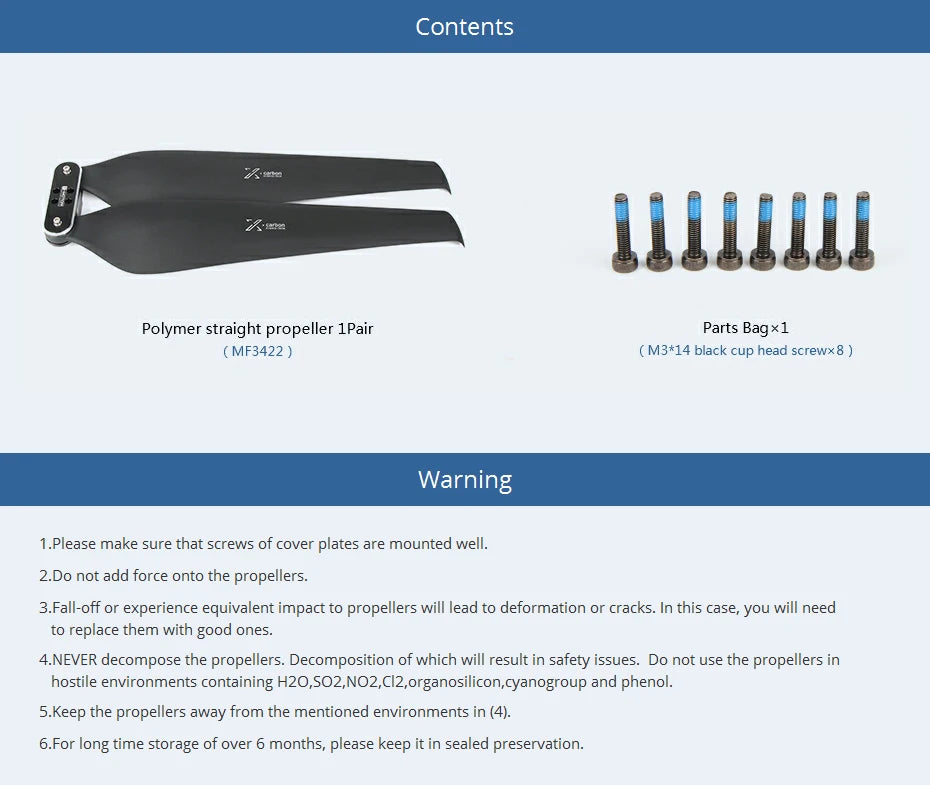

Important Safety Notice: When assembling the T-motor MF3016/MF2211 propeller, please ensure that the screws on the cover plates are securely tightened. Failure to do so may cause the propeller to deform or crack if it falls off or experiences an equivalent impact. Additionally, never attempt to disassemble the propeller as this can lead to safety issues.

Carbon fiber hybrid propellers offer lightweight, durable construction with a low moment of inertia.

3nOTO J e a MF3422R Multi (Props for multi-rotors) CCW (L for CW) 22kg (Max. thrust provided by the prop)

The X-Carbon propellers are made from a combination of carbon fiber and polymer materials. They feature a heat-insulating coating achieved through high-shading injection technology, with a surface texture precision-engineered to a depth of 0.25mm.

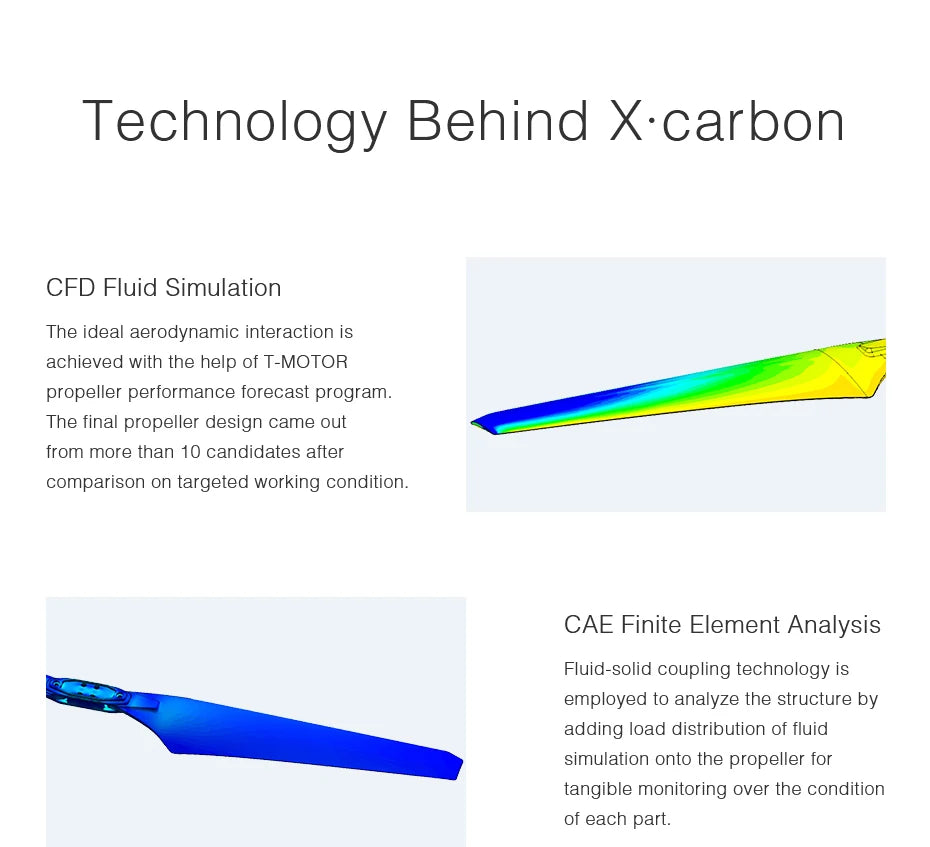

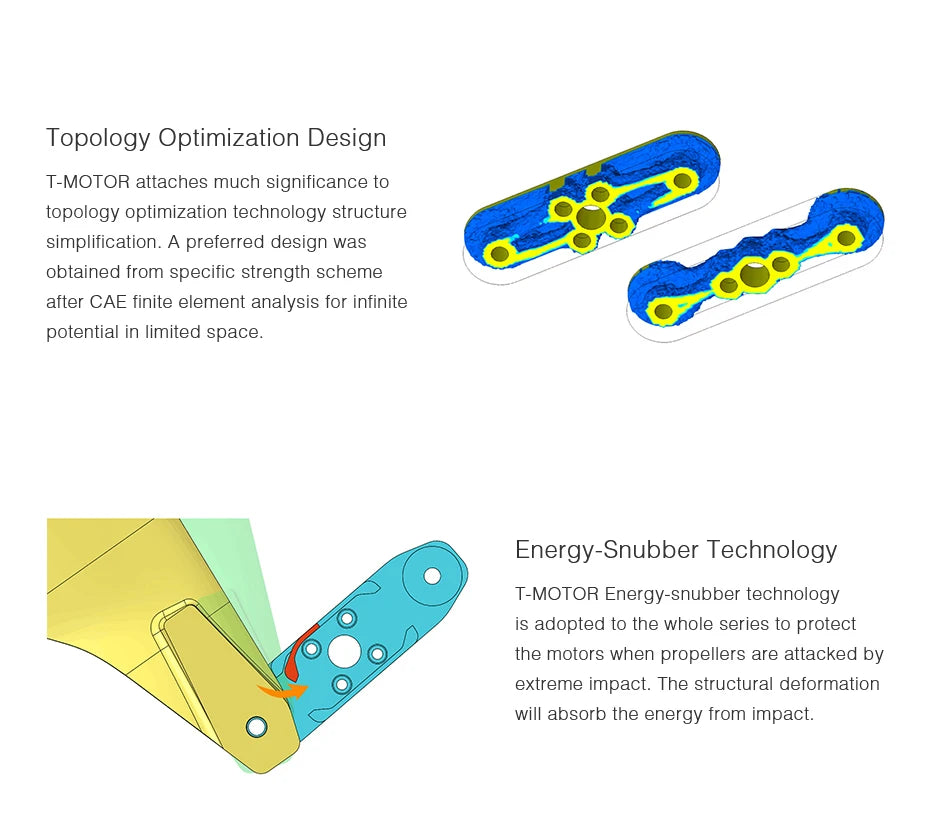

After evaluating over 10 design options, we selected the final propeller design based on its performance in targeted working conditions. To optimize the structure's integrity, we employed finite element analysis and combined it with fluid simulation load distribution to thoroughly analyze the propeller's behavior.

T-MOTOR emphasizes the importance of topology optimization technology, which simplifies structure design through specific strength schemes achieved via CAE finite element analysis. This optimized design enables infinite potential within limited space, allowing for effective energy absorption during impact-induced structural deformation.

The research and development team at T-MOTOR has optimized the magnetic circuit design of their motors and Alpha Electronic Speed Controllers (ESCs) to provide an exceptional flying experience.

A superior texture was applied to ensure exceptional craftsmanship and high-quality construction.

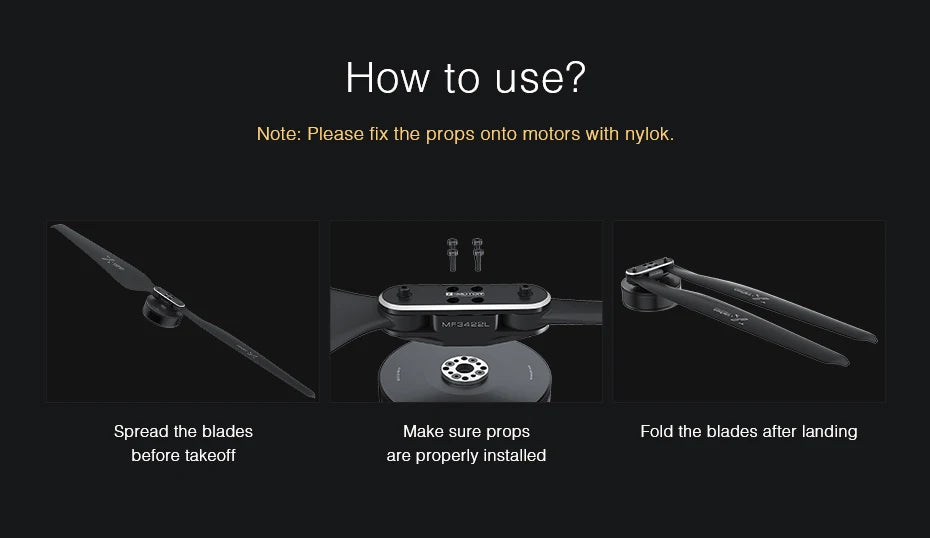

Secure the propellers to the motors using Nylok fasteners. Ensure that the blades are evenly spaced and properly installed for optimal performance. Additionally, confirm that the propellers fold correctly after landing and before takeoff.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...