T-MOTOR MF2412 Polymer Folding propeller SPECIFICATIONS

Brand Name: T-MOTOR

Origin: Mainland China

Material: Carbon Fiber

Recommend Age: 14+y

RC Parts & Accs: Propellers

Size: MF2412

For Vehicle Type: Helicopters

Use: Vehicles & Remote Control Toys

Upgrade Parts/Accessories: motor

Remote Control Peripherals/Devices: ESC

Tool Supplies: Battery

Model Number: MF2412

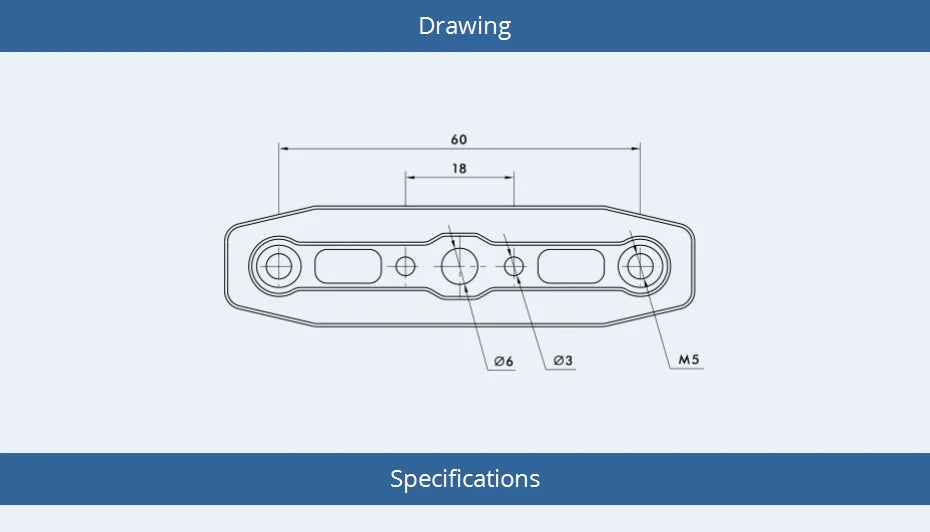

MF2412 T-MOTOR Series Folding Weight 96g Package Weight 327g (Single Blade) Diameter 24.4inch(619.8mm) Package Size 305*127*48mm Pitcn 8.7inch(221.3mm)

carbon PRINCIPLE Propellers of light weight, durable density and small moment of inertia: I - carbon Myorid-Tech .

The T-MOTOR MF2412 polymer folding propeller, designed specifically for VTOL multi-copters and drones, offers an easy choice naming convention to simplify selecting the right propeller. The 'R' designation indicates counter-clockwise rotation (CCW), while the 'L' designation is for clockwise rotation (CW). This propeller is suitable for use on multi-rotors.

Through continuous innovation and refinement, we've developed an advanced injection molding process that combines the benefits of carbon fiber and polymer materials to create our new Xcarbon propellers. This hybrid technology offers enhanced properties, including: 1.5x-3.5x abrasion resistance, increased material density, and improved prop strength.

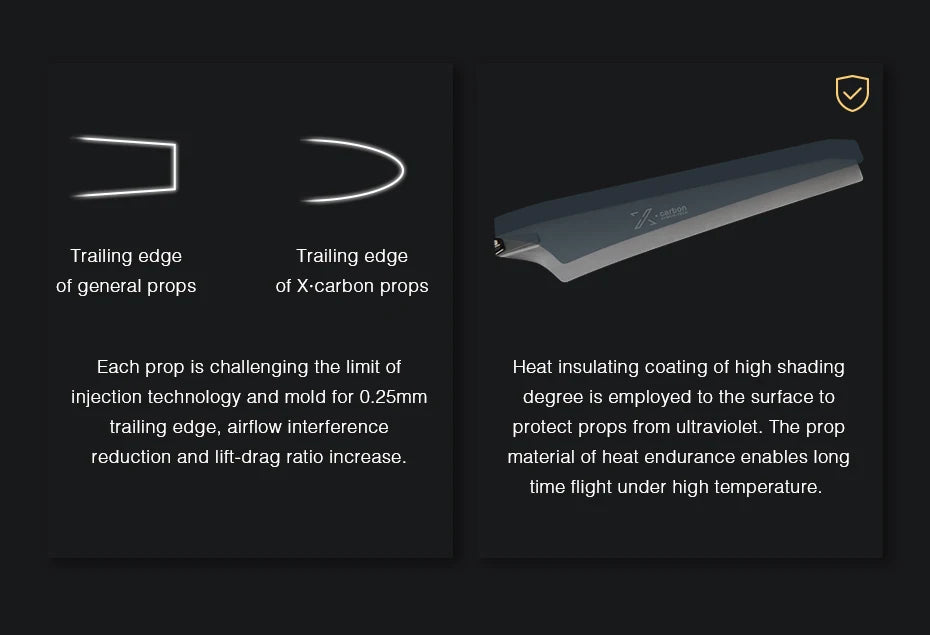

The T-MOTOR MF2412 features a precision-molded polymer design with a thickness of 0.25mm, which provides optimal protection for the trailing edge surface from airflow interference. Additionally, this innovative design helps reduce propellers' exposure to ultraviolet (UV) rays, while also enhancing their lift-to-drag ratio and overall efficiency.

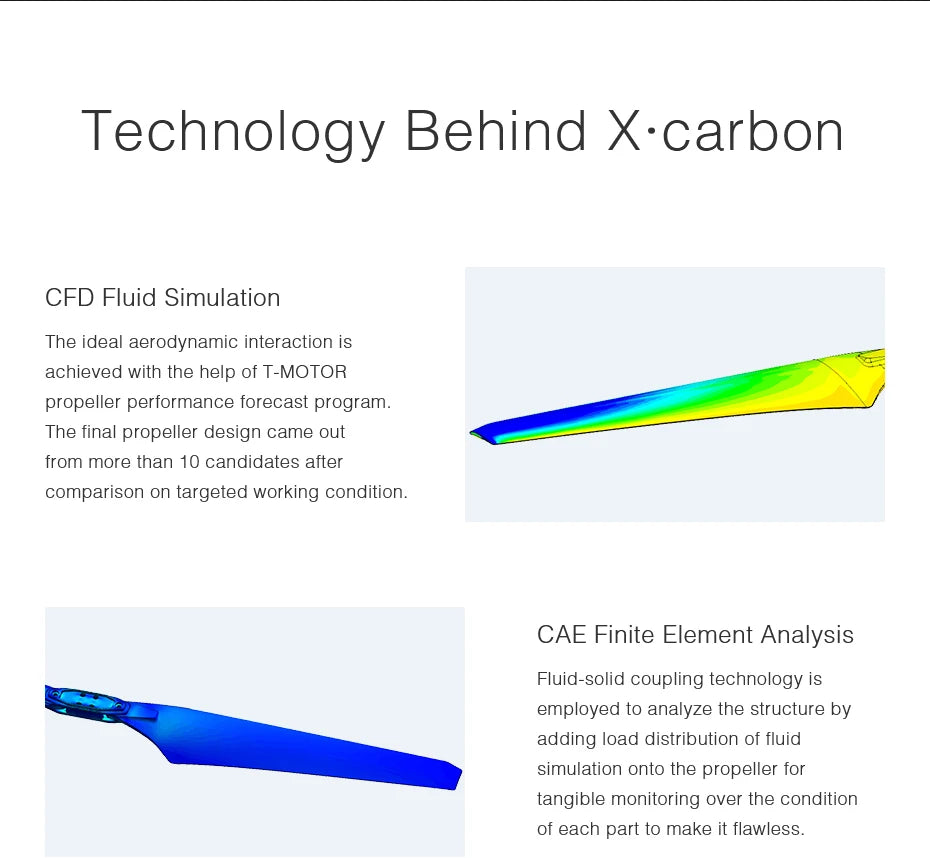

After comparing over 10 design options, our team selected the optimal final design for the targeted working condition. The X-Carbon propeller was developed using T-MOTOR's proprietary propeller forecasting program.

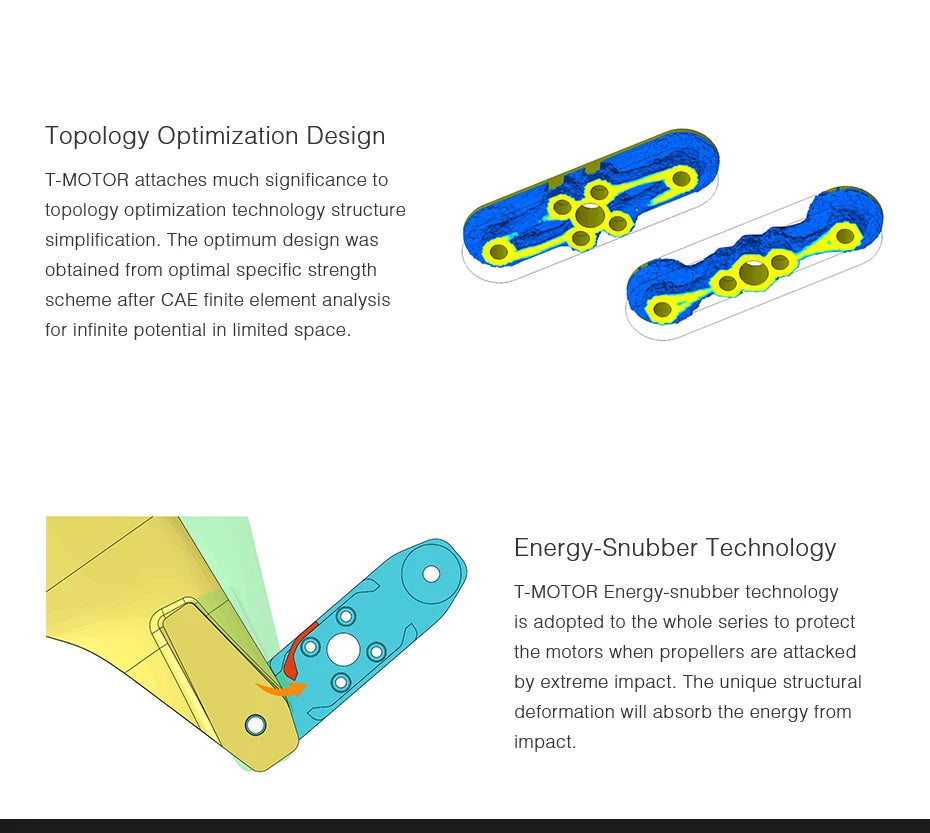

The T-MOTOR MF2412 features an innovative energy-snubber technology that effectively protects the motors during propeller strikes by absorbing the impact's energy through its unique structural design, allowing for reduced shock transmission and enhanced overall stability.

The same high-strength steel used in the motor shaft prevents the propeller's spindles and screws from bending. The 7075 aluminum alloy, treated with anodizing for added protection, offers a lightweight, durable, and rust-resistant construction.

The ideal combination with T-MOTOR's Alpha ESCs and motors involves the optimization of the magnetic circuit design by our R&D team, ensuring a superior flying experience with fast response times.

Featuring superior texture, our product has undergone rigorous testing, including 100,000-fold folding tests, to guarantee exceptional craftsmanship and quality.

Secure the propellers to the motors using Nylok fasteners: Ensure the blades are evenly spaced and properly secured before taking off.

Related Collections

Explore More Drones & Accessories

-

Camera Drone

Our Camera Drone Collection features a wide range of brands including FIMI,...

-

Drone Accessories

Discover a wide range of drone accessories to enhance flight performance, extend...